Scrap Shear

high force, high speed

and good weight ratio

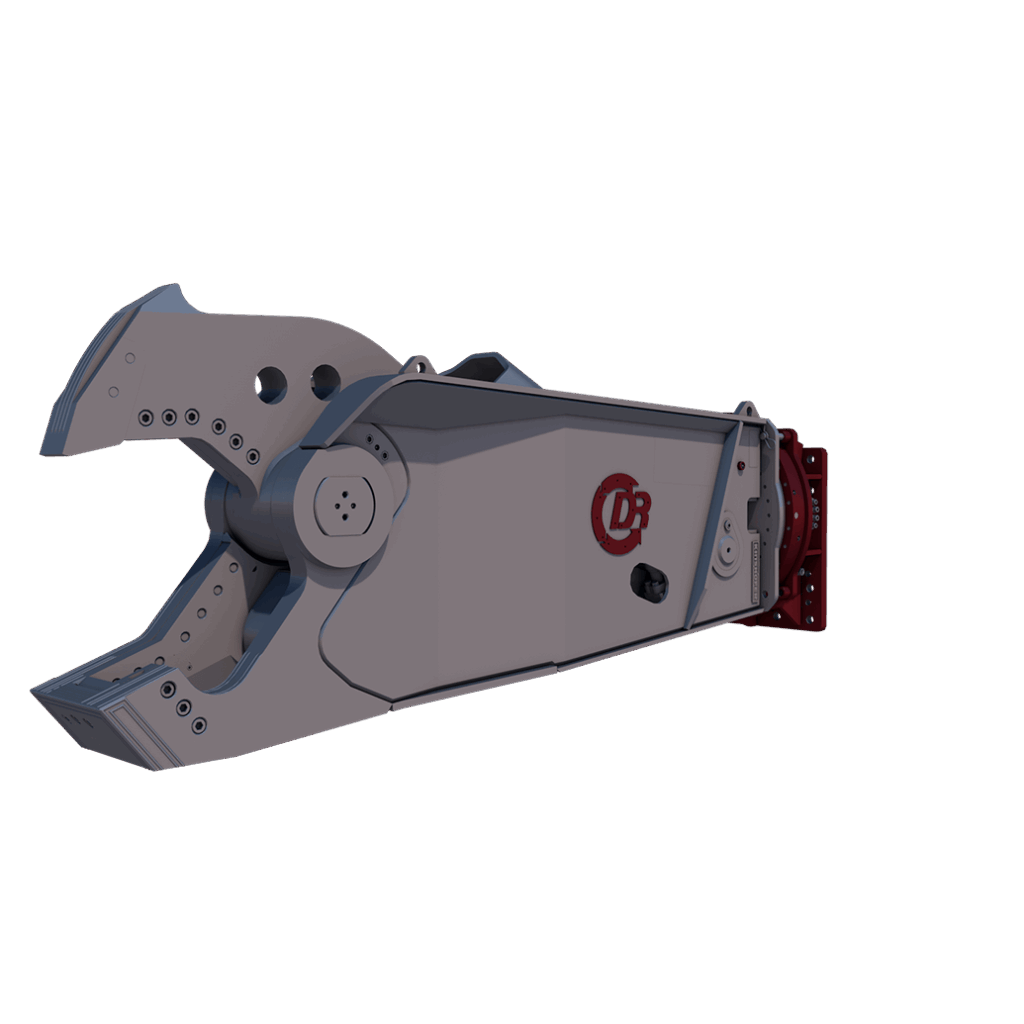

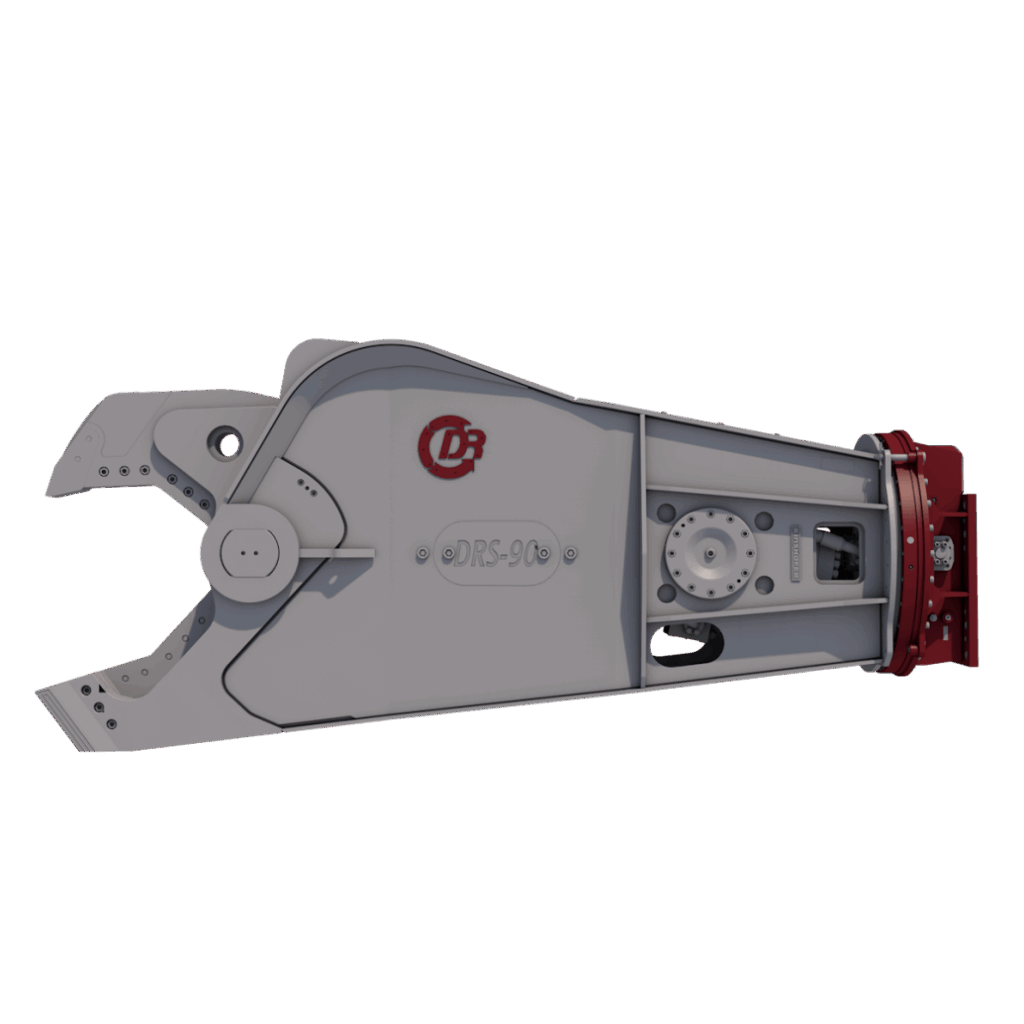

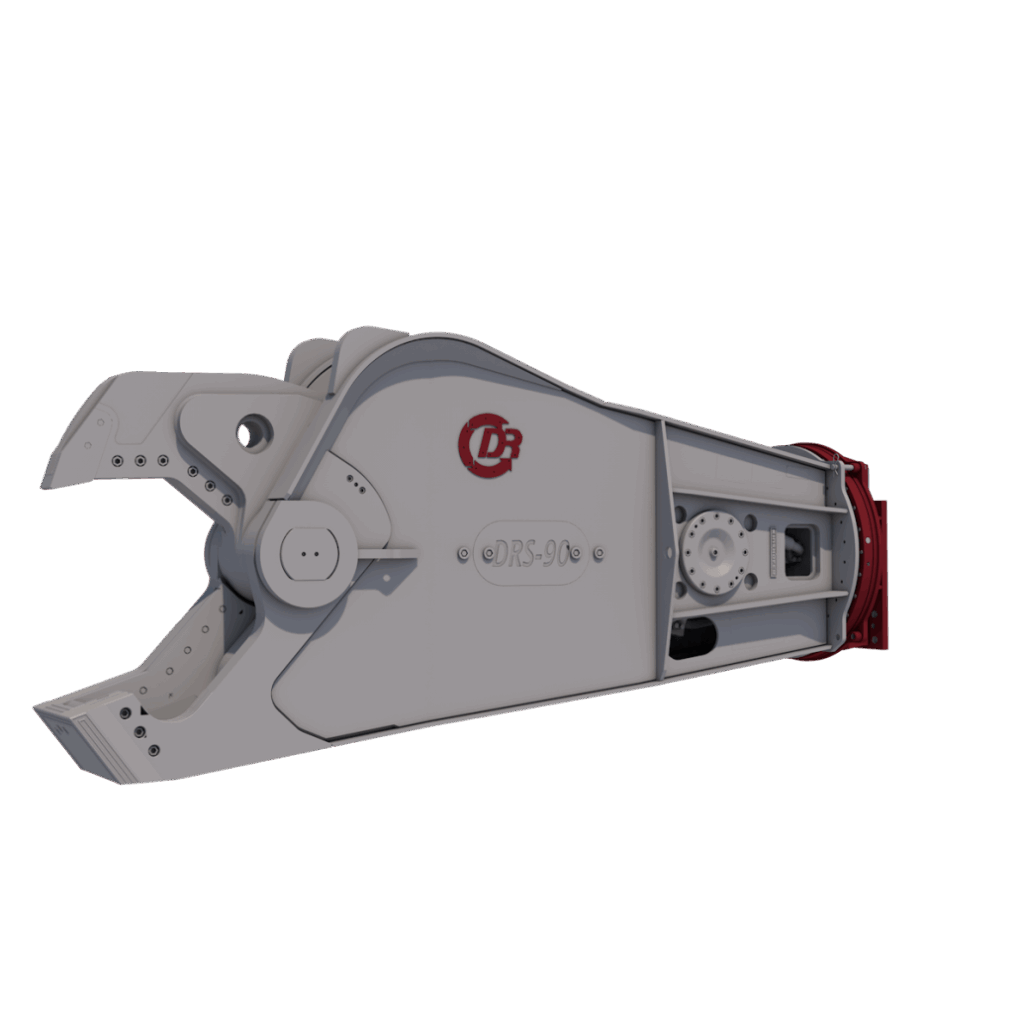

The Demarec DRS mobile shear was engineered to deliver a scrap shear with a high force, high speed and good weight ratio for a good performance in daily use on scrap yards and demolition sites. This robust tool can be used for a wide variety of jobs including demolition, scrap processing and tire recycling. With three different mounting options, the DRS scrap shear is available in six different sizes, suitable for excavators from 14 until 100 ton operating weight.

High force, high speed and good weight ratio

or a good performance in daily use

on scrap yards and demolition sites

Key features & benefits

Shear Arm

Massive shear arm

Heavy duty slim shear arm design guarantees an optimal penetration

Out of Hituf

Bearings

Induction-hardened pins are seated insteel bearings

DemaGuide

Hardened lateral guide plates provide a stable support of the shear arm within the main bearing for a longer lifetime (Shear Arm Guide System SGS)

DemaBlade

Optimal mouth design with large opening

More cutting capacity due to offset APEX of shear blades

Piercing tip is exchangeable and re-weldable

All blades can be released from the outside

Blade Locking System (BLS) in upper and lower jaw

Performance to Weight Ratio

Endurance tests as well as FEM stress calculations confirm the weight optimized design and provide an ideal weight / power ratio

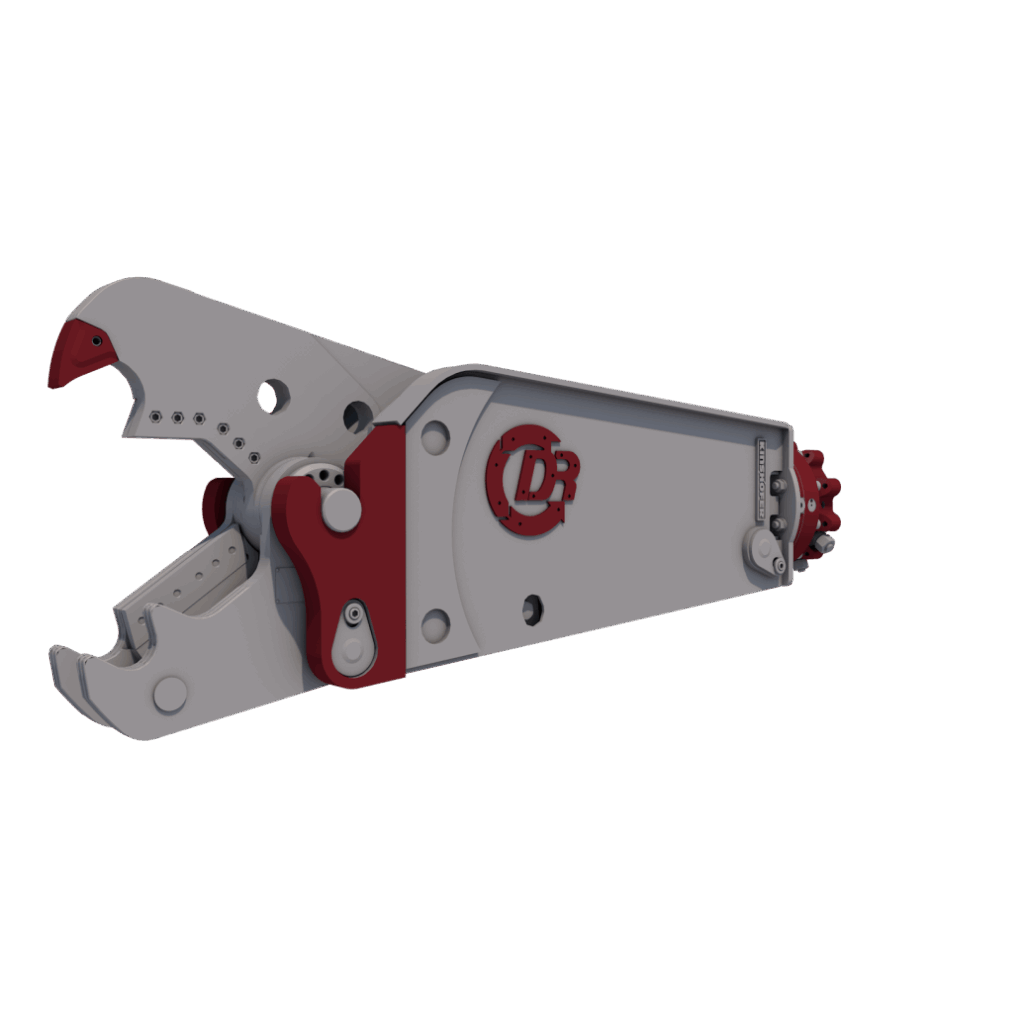

Heavy Duty Rotation

360° continuous rotation (shear also available without rotation). Oversized slewing ring is able to bear high forces, shock loads and bending moments

Filters in rotation circuit

2 Heavy duty motors for a maximum rotation torque (DRS 25-45)

One powerful piston Motor with drain line (DRS60-9

DemaFilter-System

in rotation circuit

Cylinder / Hydraulics

Strong long-stroke cylinder with speed valve

Trunnion design of the hydraulic cylinder results in an overall shorter shear length

Center of gravity closer to the machine adds to higher stability

Cylinder completely protected within the body

High capacity swivel helps to avoid high oil temperature and to ensure high oil flow / speed

Fast cycle times

Shear Body

Strong box design made of high-strength fine grained steel the shear body ensures highest strength

Fast access to hoses and hydraulics through service openings

| Type | Weight* | Length | Jaw opening | Jaw depth | Primary cutter | Cutting force | Operating weight (boom) | Operating weight (stick) |

|---|---|---|---|---|---|---|---|---|

| DRS-25-A | 2150 kg | 2740 mm | 500 mm | 460 mm | 180/280 mm | 4592 kN | 14 – 20 ton | 20 – 30 ton |

| *Excl adapter | ||||||||

| **Depending of lifting capacity of carrier. Subject to change without notice |

Download our free

DRS brochure

Want to know more about our Scrap shears?

Download the brochure for more info by filling out the form below.

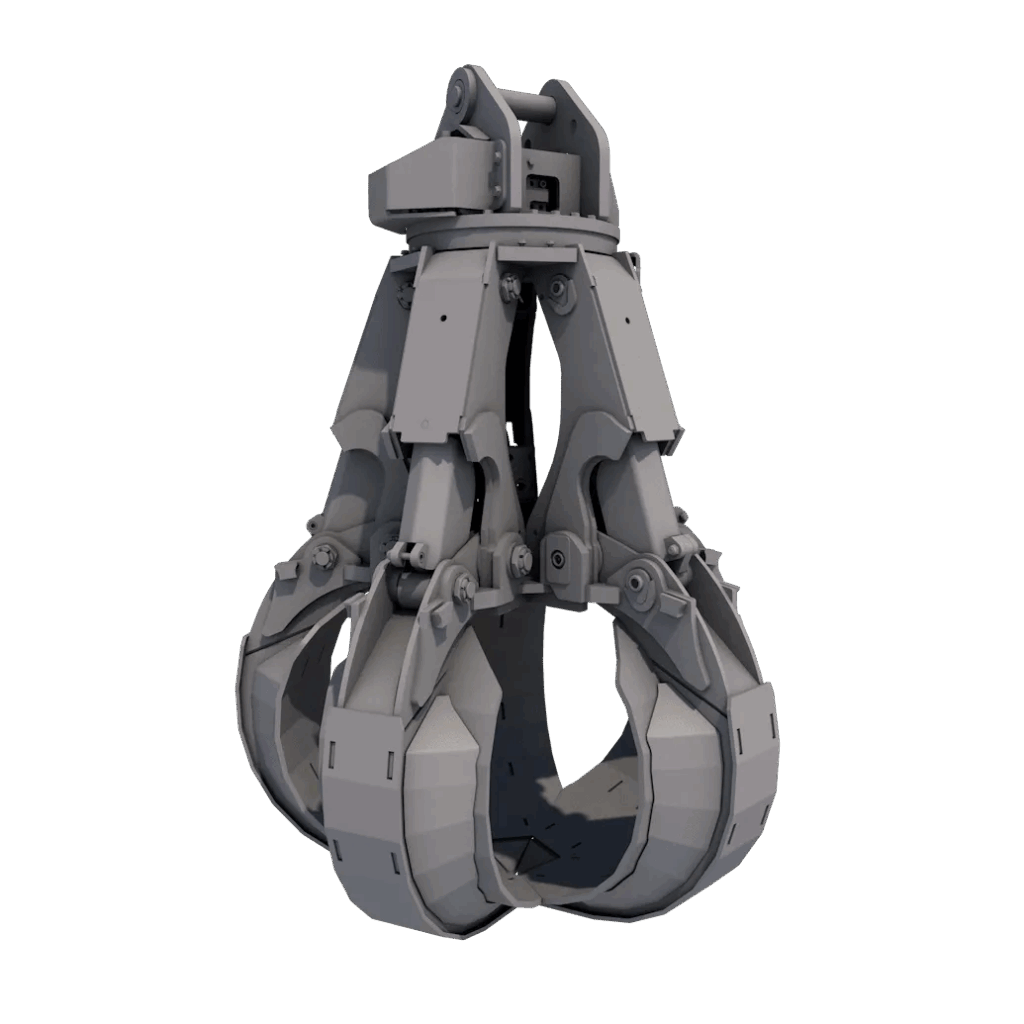

Related products

Request quote

We will get back to you as soon as possible.

Frequently asked questions

Can’t find what you are looking for?

Here are the most asked questions and their answers!

What demolition recycling scrap handling and construction attachments are included in Demarec’s product range?

Demarec has separate product lines with the PremiumLine and ProLine for Demolition and Recycling,

Scrap and Recycling, and Construction. Key tools include demolition and sorting grabs,

pulverizers, multi quick processors, two cylinder concrete crushers, hydraulic hammers, multi shears, drum cutters, scrap shears, rail cutters, polyp grabs, rotatable pulverizers, tilt rotators and more.

How does the patented DemaPower System boost the power and cycle speed of Demarec tools?

The four chamber DemaPower cylinder delivers about twenty five percent more closing force and cycles faster because two chambers work on the in stroke and two on the out stroke. A double acting speed valve keeps oil moving both ways, so the jaw opens and closes in roughly five seconds while staying within normal excavator pressure.

Where can I obtain spare parts maintenance, repairs for my Demarec attachment or who do I call for urgent technical assistance if my Demarec tool develops a fault on site after purchase?

Demarec runs an in house service department and After Sales portal. For help you can phone +31 485 442 300 option 2 for parts or option 3 for service, or write to parts@demarec.com and service@demarec.com. Local dealers worldwide can also supply parts and support.

I would like to represent Demarec what steps should I follow to become an authorised dealer?

Fill out the short enquiry form on the Become our dealer page. Demarec will review the details and respond directly.

Does Demarec offer training facilities to dealers?

Yes we have our inhouse training center for service and sales.

How do I determine which Demarec attachment model fits the size and hydraulic capacity of my carrier excavator or material handler?

Every product page and brochure includes a technical specification table that lists carrier weight windows, tool weight, oil flow and pressure. Match your machine to those ranges or ask Demarec service for confirmation. Example: DRG selector grabs cover carriers from ten to eighty tons with detailed specs-per-model.