Static

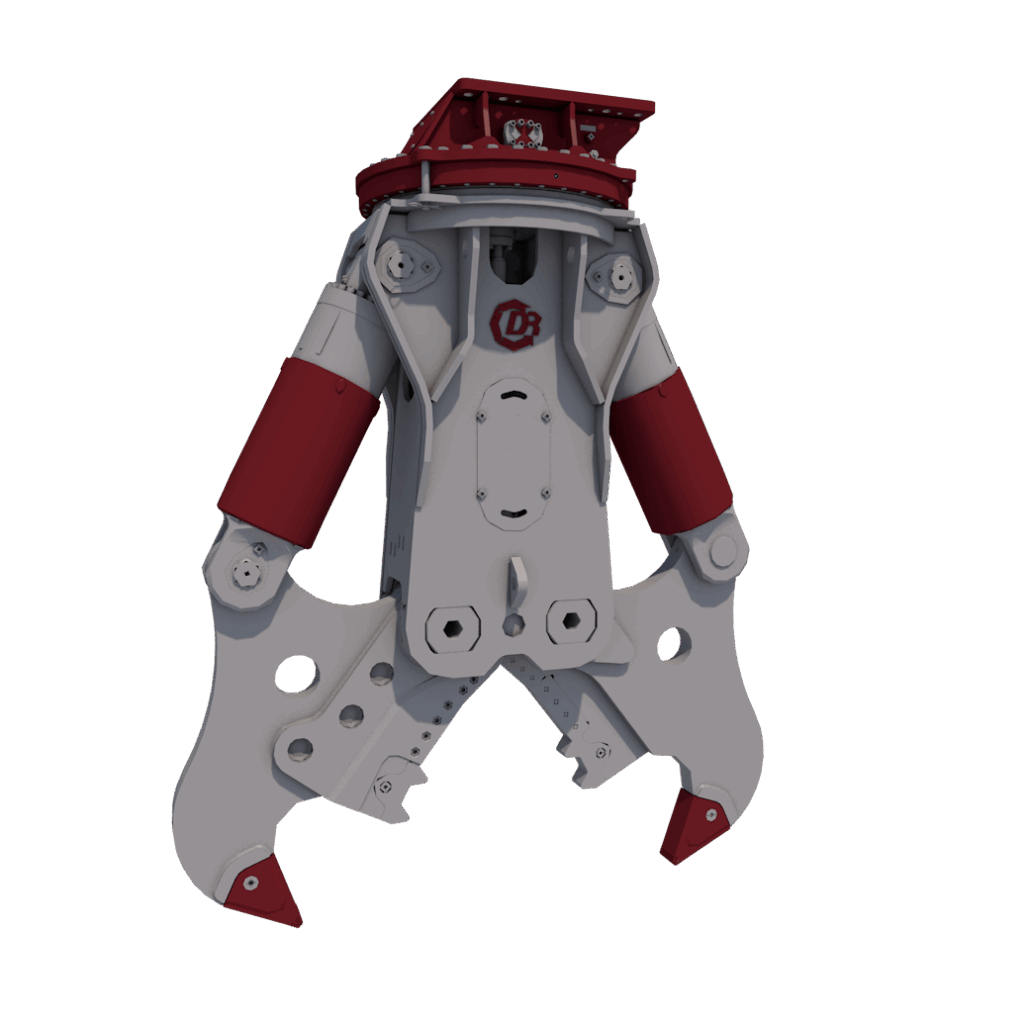

pulverizers

Developed for

secondary demolition

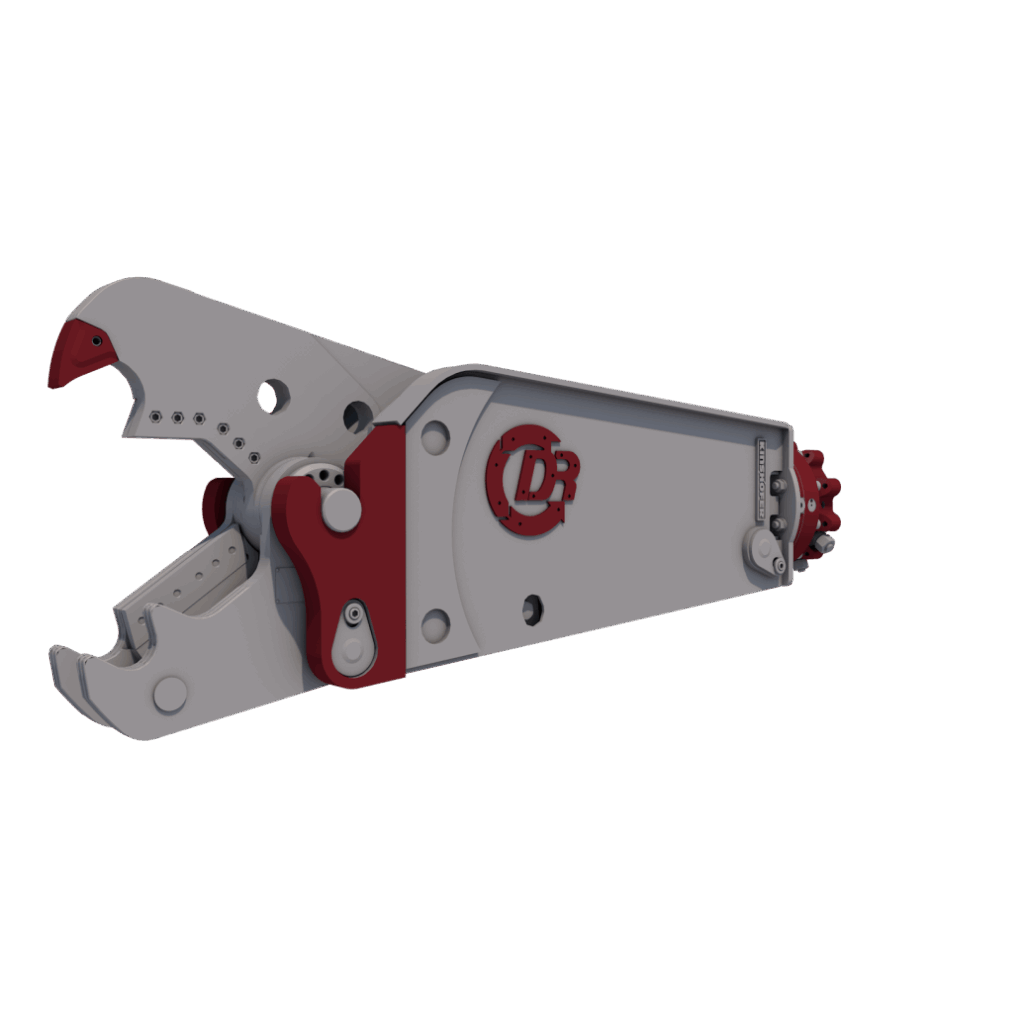

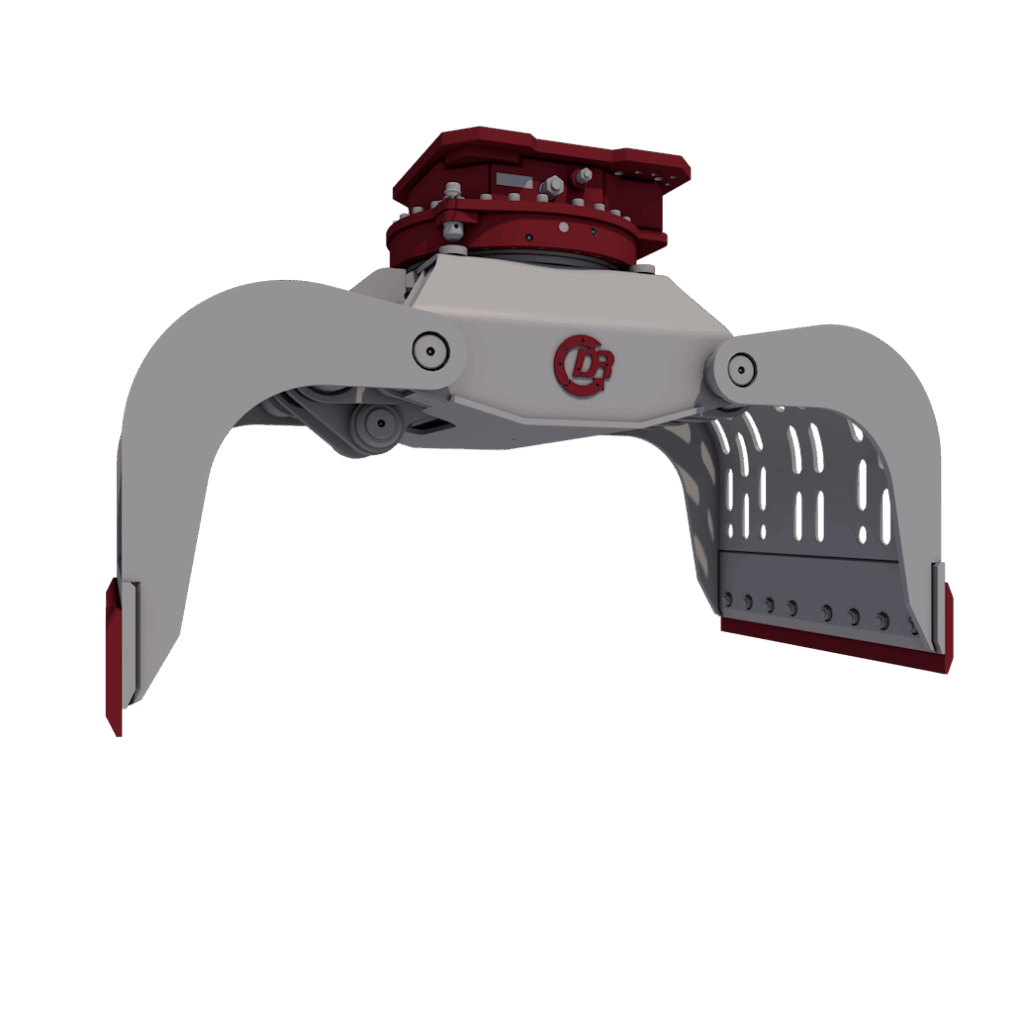

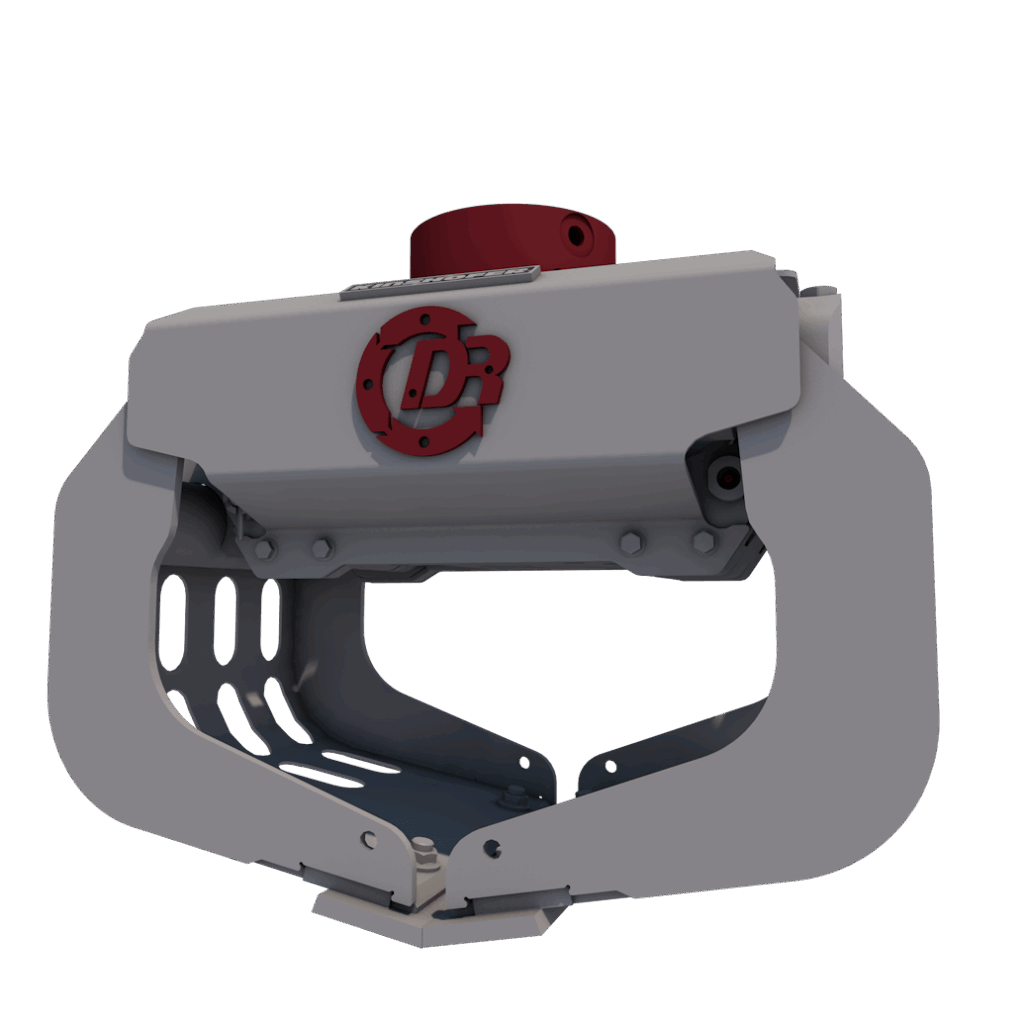

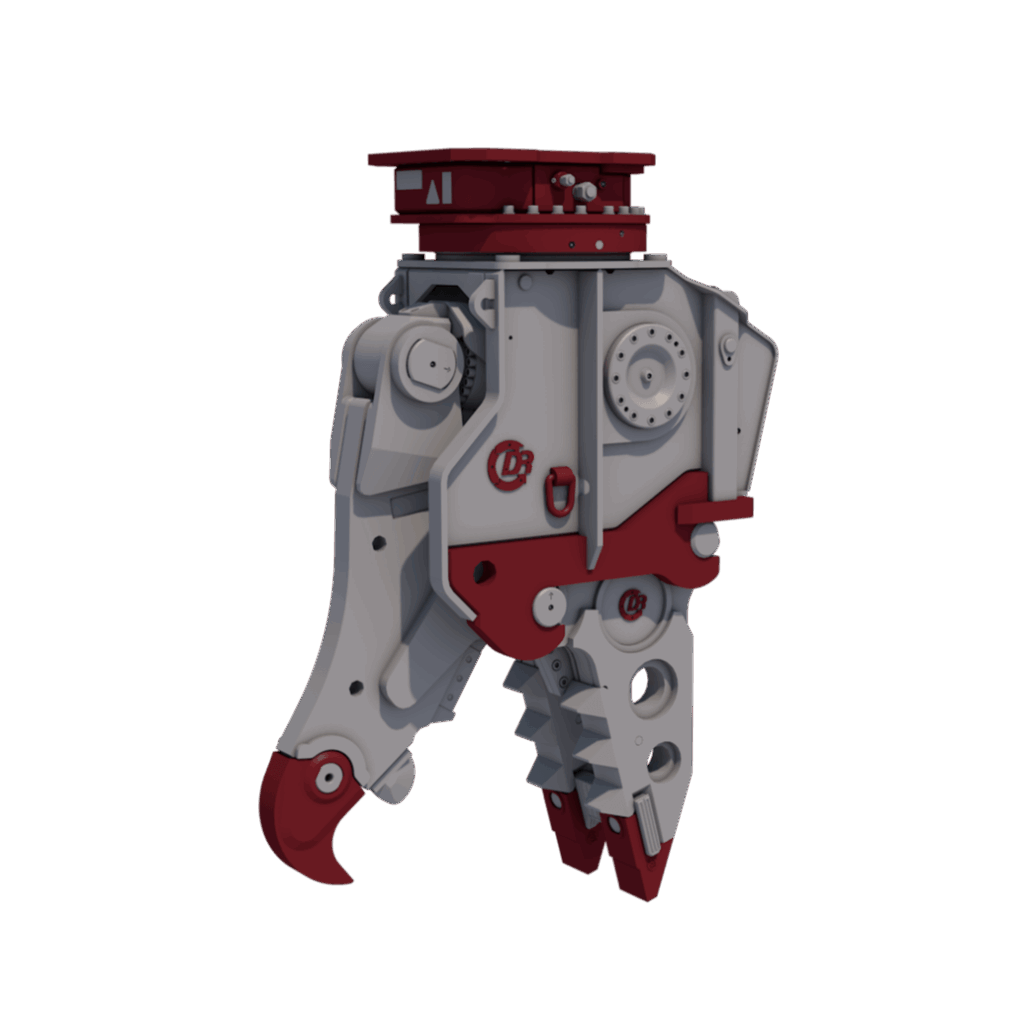

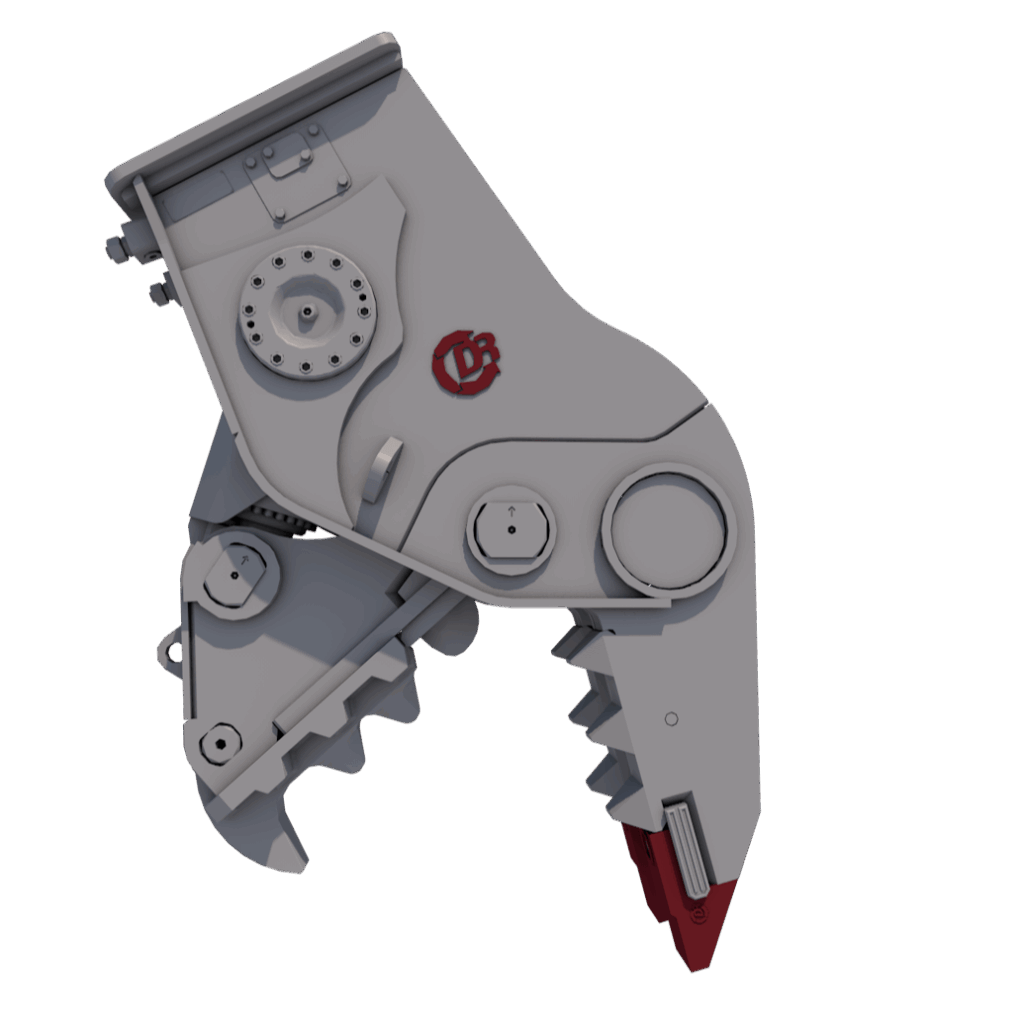

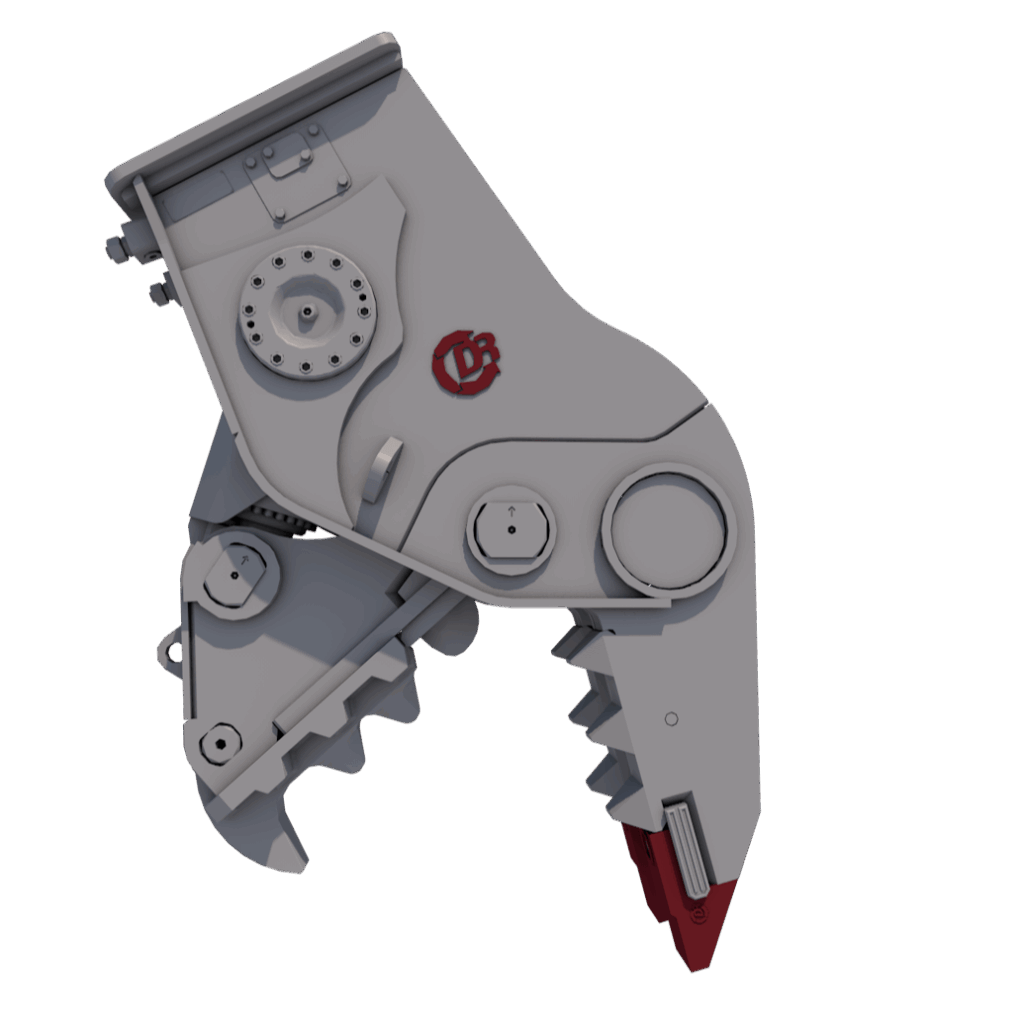

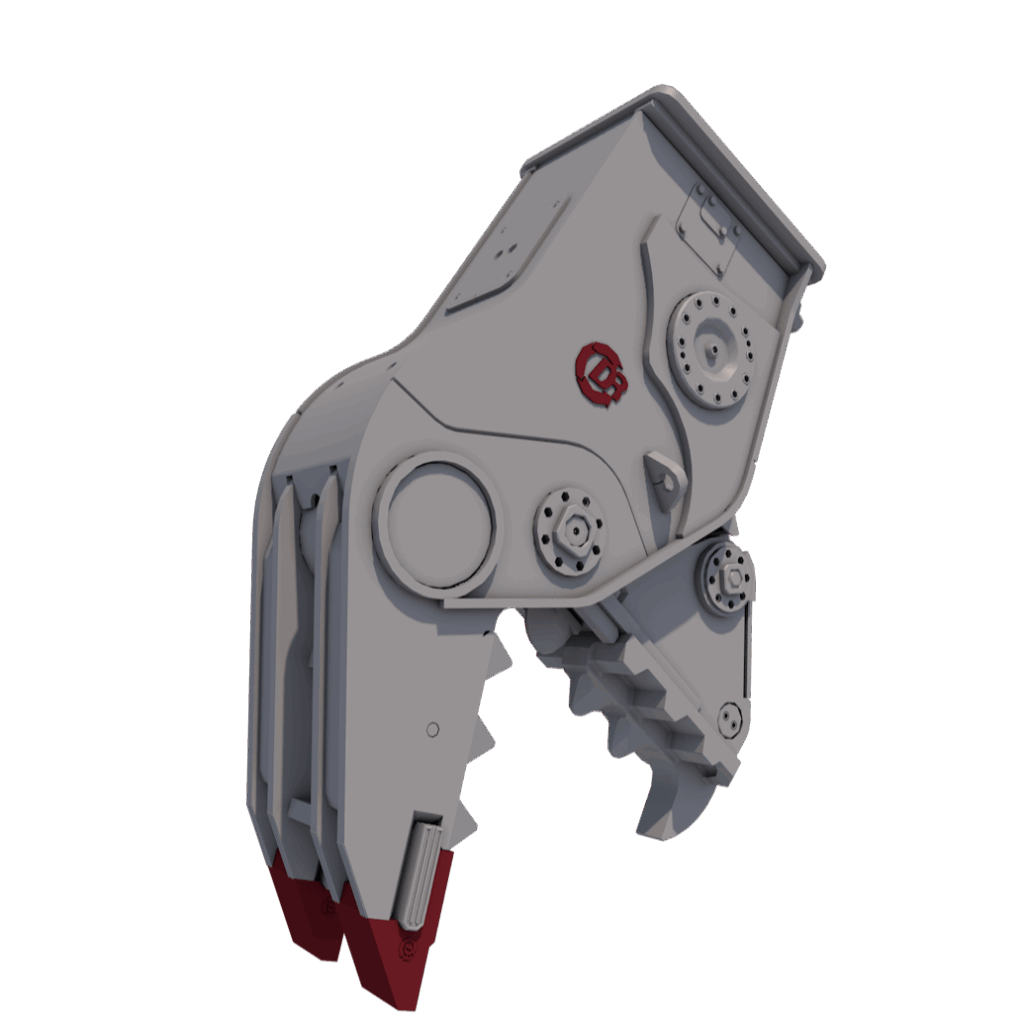

The Demarec Pulverisers have been developed for secondary demolition – breaking concrete and freeing reinforced steel bars. Pulverising at the demolition site reduces the costs of transport and recycling. The Extreme version of the DSP-series is equipped with the “well known” DemaPower-System! A unique cylinder technique: 20% more power and extremely fast cycle times. The upper jaw has a ground tooth plate that has one front tooth which ensure outstanding penetration into the concrete. Both teeth in the upper jaw are between the shrouds in the lower jaw, so the reinforced steel is always optimally separated from the concrete.

Wear parts

can be changed on site

All wear parts can be changed on site. No need to transport the pulverizer to the workshop. Demarec pulverisers are supplied without cutting blades as standard. This means that the reinforcing steel can be optimally separated from the concrete without small pieces of steel being cut off. Also available in rotating version (DSP-R)

20% more power

Extremely fast cycle times

4-5s

Extremely fast cycle times

Double

Pressure chambers

Key features & benefits

Exchangeable tooth plate

DemaPower-System

A unique cylinder technique: 20% more power andextremely fast cycle times!

(The Extreme version of the DSP-series is equiped with the “well known” DemaPower-System!)

Overdimensioned pivot point

Exchangeable parts

Exchangeable shrouds.

Exchangeable cutting edges (optional)

Exchangeable scrap teeth.

design cylinder

| Type | Carrier weight* | Weight** | Additional weight rotating | Closing force | Jaw opening | Width upper jaw | Width lower jaw | Jaw depth | Height | Length of cutting blades*** |

|---|---|---|---|---|---|---|---|---|---|---|

| DSP-30 | 20 – 35 ton | 2135 kg | +375 kg | 80 / 125 ton | 885 mm | 350 mm | 490 mm | 840 mm | 2145 mm | 200 mm |

| DSP-30 EXTREME | 20 – 35 ton | 2115 kg | +375 kg | 100 / 150 ton | 885 mm | 350 mm | 490 mm | 840 mm | 2145 mm | 200 mm |

| DSP-45 | 30 – 50 ton | 2670 kg | +375 kg | 110 / 150 ton | 1015 mm | 400 mm | 525 mm | 900 mm | 2360 mm | 200 mm |

| DSP-45 EXTREME | 30 – 50 ton | 2645 kg | +375 kg | 130 / 185 ton | 1015 mm | 400 mm | 525 mm | 900 mm | 2360 mm | 200 mm |

| DSP-60 EXTREME | 42 – 65 ton | 3525 kg | +550 kg | 150 / 205 ton | 1135 mm | 450 mm | 565 mm | 1000 mm | 2635 mm | 200 mm |

Download our free

DSP brochure

Want to know more about our Pulverizers?

Download the brochure for more info by filling out the form below.

Related products

Request quote

We will get back to you as soon as possible.

Frequently asked questions

Can’t find what you are looking for?

Here are the most asked questions and their answers!

What demolition recycling scrap handling and construction attachments are included in Demarec’s product range?

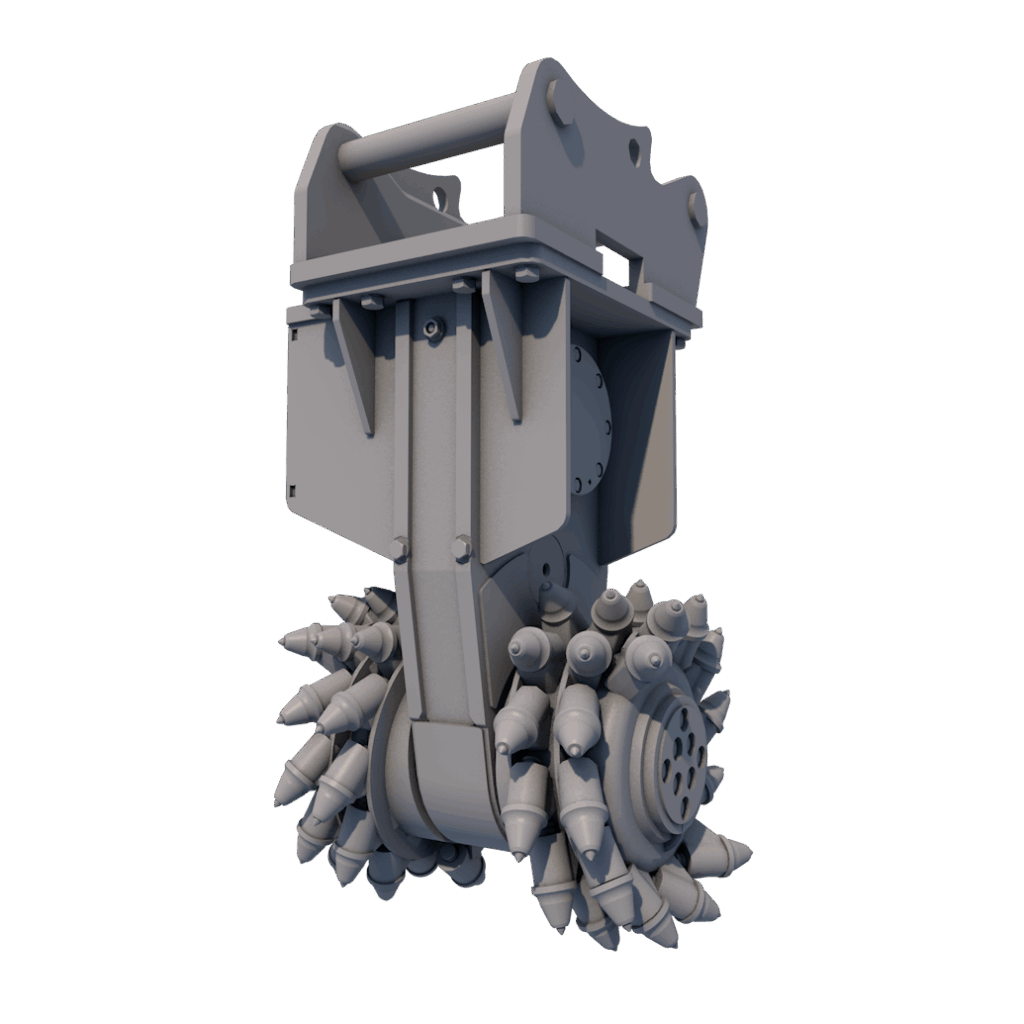

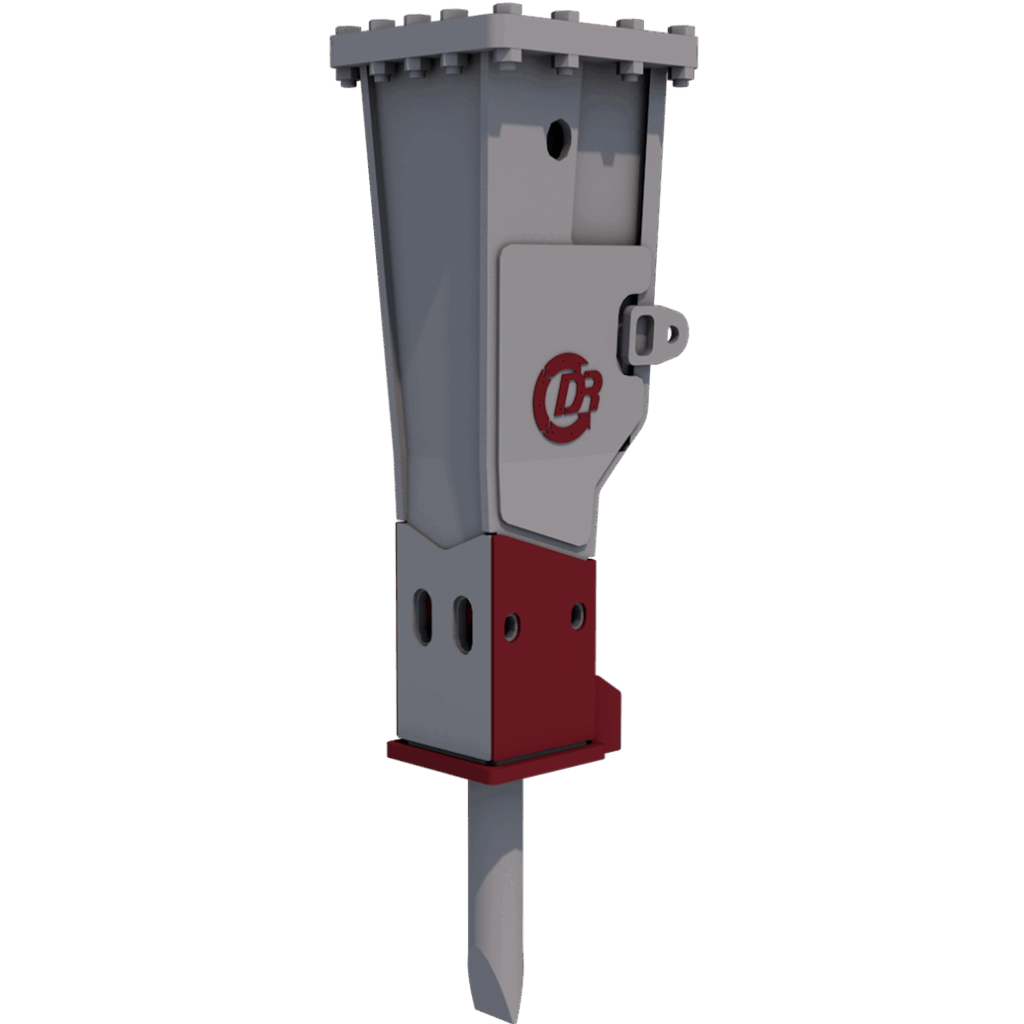

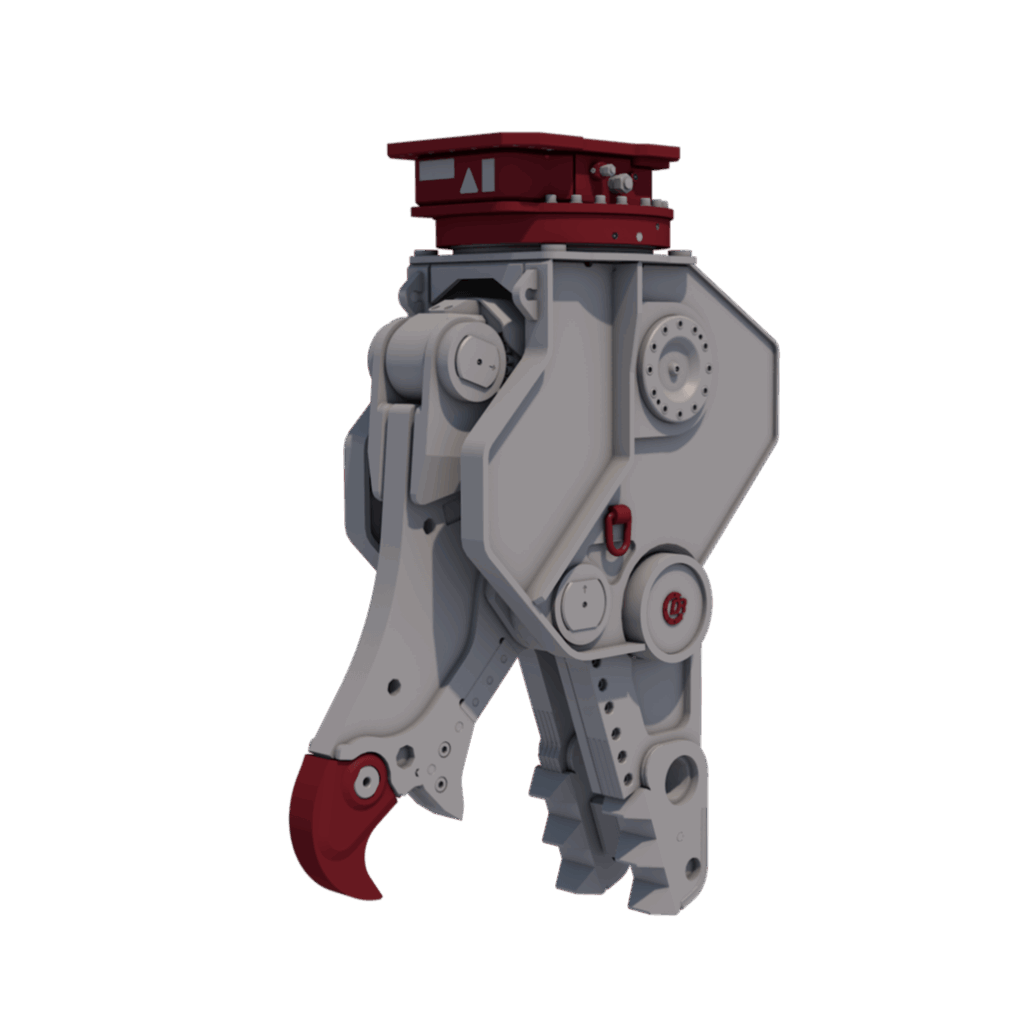

Demarec has separate product lines with the PremiumLine and ProLine for Demolition and Recycling, Scrap and Recycling, and Construction. Key tools include demolition and sorting grabs, pulverizers, multi quick processors, two cylinder concrete crushers, hydraulic hammers, multi shears, drum cutters, scrap shears, rail cutters, polyp grabs, rotatable pulverizers, tilt rotators and more.

How does the patented DemaPower System boost the power and cycle speed of Demarec tools?

The four chamber DemaPower cylinder delivers about twenty five percent more closing force and cycles faster because two chambers work on the in stroke and two on the out stroke. A double acting speed valve keeps oil moving both ways, so the jaw opens and closes in roughly five seconds while staying within normal excavator pressure.

Where can I obtain spare parts maintenance, repairs for my Demarec attachment or who do I call for urgent technical assistance if my Demarec tool develops a fault on site after purchase?

Demarec runs an in house service department and After Sales portal. For help you can phone +31 485 442 300 option 2 for parts or option 3 for service, or write to parts@demarec.com and service@demarec.com. Local dealers worldwide can also supply parts and support.

I would like to represent Demarec what steps should I follow to become an authorised dealer?

Fill out the short enquiry form on the Become our dealer page. Demarec will review the details and respond directly.

Does Demarec offer training facilities to dealers?

Yes we have our inhouse training center for service and sales.

How do I determine which Demarec attachment model fits the size and hydraulic capacity of my carrier excavator or material handler?

Every product page and brochure includes a technical specification table that lists carrier weight windows, tool weight, oil flow and pressure. Match your machine to those ranges or ask Demarec service for confirmation. Example: DRG selector grabs cover carriers from ten to eighty tons with detailed specs-per-model.