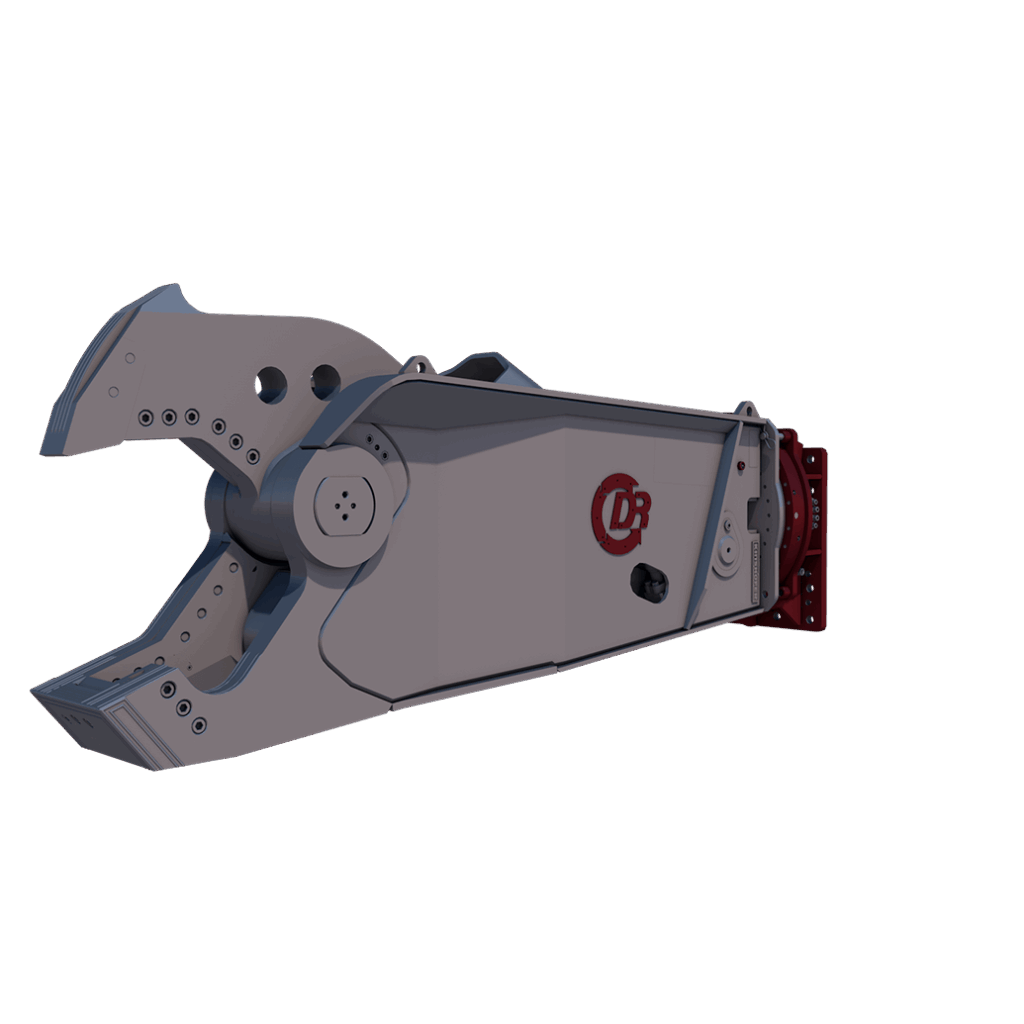

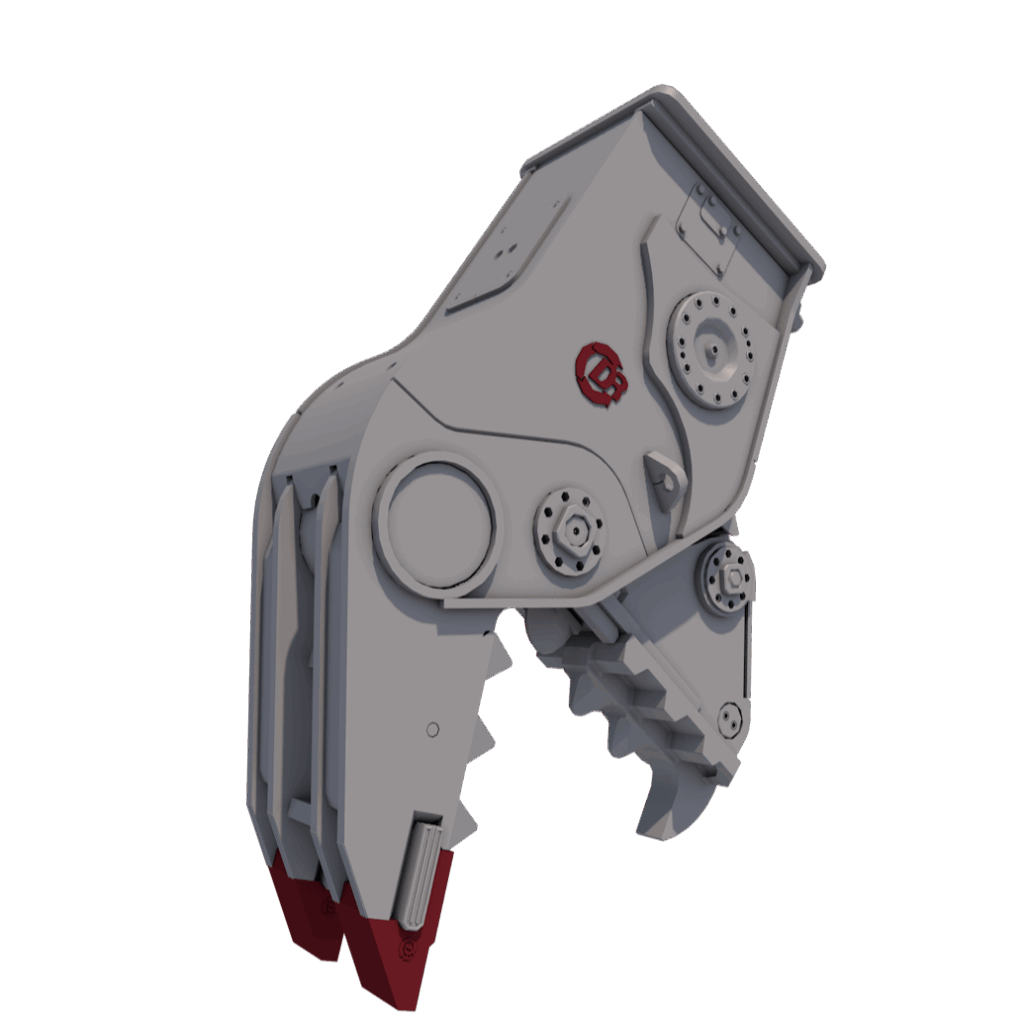

Rotating

pulverizers

Exchangeable

wear parts

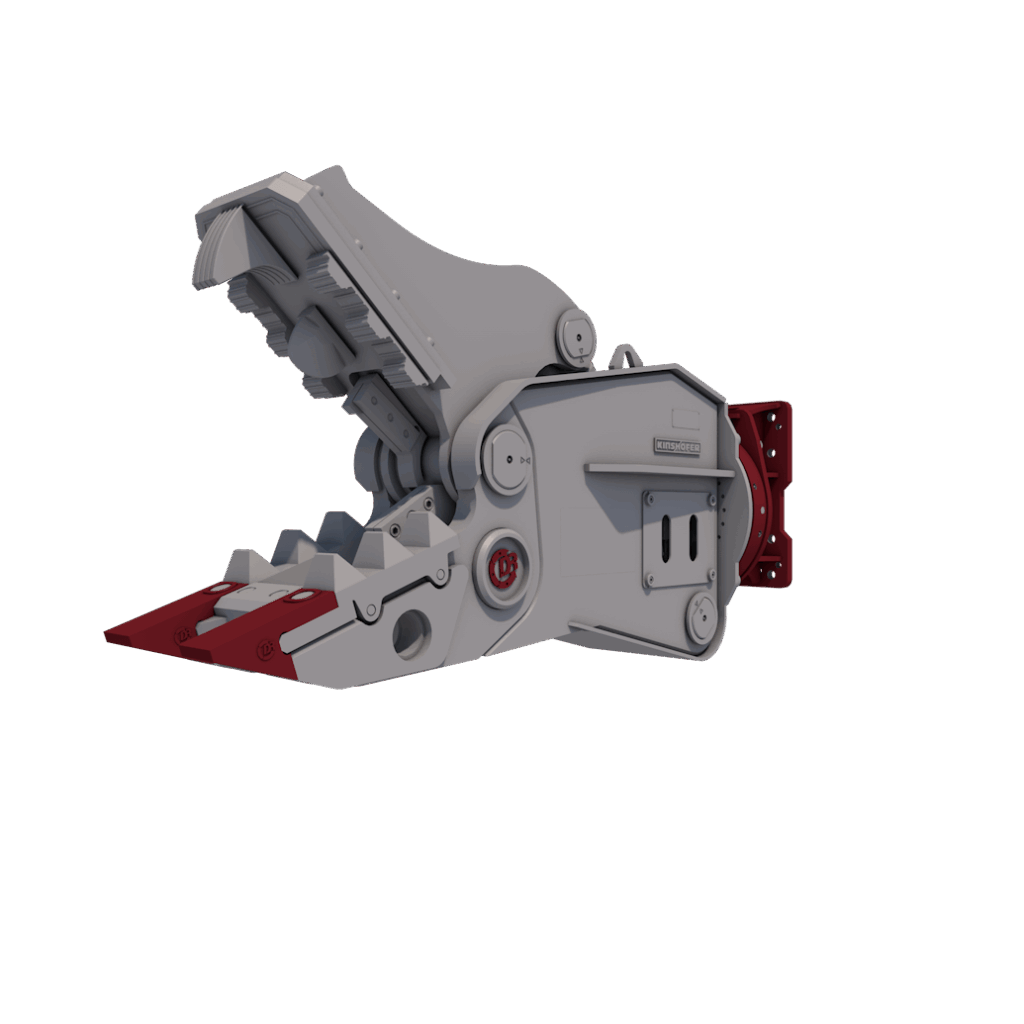

The new ProLine DLP-models in the dedicated demolition line are special designed to have a competitive rotatable pulveriser in the market with the full Demarec DNA.

It’s a concept with mostly new exchangeable wear parts. Also these new pulverisers can be used in primary and secondary demolition.

no concessions

to quality

With this new line of pulverizers we are focusing on a new target group. The pulverizers are intended for 32 tons excavators down to 9 ton. During the development we have not made any concessions to quality, but have mainly looked at possibilities to develop a product with a more advantageous final price for the customer.

standard

cylinder

The ProLine, which is marketed under the name Demarec ProLine, has a simpler, standard cylinder technology and a different technical structure, including a different tooth plate system. The Demarec philosophy of fully exchangeable wear parts has also been implemented in the new DLP line.

Exceptional

price to performance

The Demarec DNA

Trendsetter

Trendsetter in

product developments

Knowledge

Technical and market knowledge in perfect harmony

New generation components

A lead over the competition due to the use of a new generation of components

Superior quality

Superior quality at market prices

Sustainability

Focus on sustainability

Low operating costs

Supplier of equipment with low operating costs

Greater longevity

Faster, higher capacity, less maintenance, low fuel consumption, greater longevity and interchangeable components

KINSHOFER GROUP

Part of the KINSHOFER GROUP

Key features & benefits

Robust pivot point

for a long service life

Speed valve

for fast cycle times

Exchangeable wear parts

Bolt on tooth plate (special design for extra stability to relieve the bolts), cutting blades, shrouds, Wear plate ad scrappertooth

Upside-down cylinder

(cylinder rod fully protected)

Redesigned rotator head

(prepared for easy installation of an OilQuick adapter plate)

Double bearing slewing ring

(from DLP-18)

Filters in rotation circuit

| Type | Carrier weight* | Weight** | Closing force | Jaw opening | Width upper jaw | Width lower jaw | Depth | Height | Length of cutting blades |

|---|---|---|---|---|---|---|---|---|---|

| DLP-9 | 7 – 10 ton | 550 kg | 35 ton | 520 mm | 265 mm | 320 mm | 540 mm | 1470 mm | 150 mm |

| DLP-12 | 9 – 15 ton | 950 kg | 45 ton | 600 mm | 310 mm | 360 mm | 605 mm | 1780 mm | 150 mm |

| DLP-16 | 12 – 18 ton | 1350 kg | 53 ton | 650 mm | 340 mm | 390 mm | 660 mm | 1910 mm | 150 mm |

| DLP-18 | 15 – 22 ton | 1700 kg | 63 ton | 715 mm | 360 mm | 390 mm | 755 mm | 2030 mm | 200 mm |

| DLP-24 | 18 – 25 ton | 2000 kg | 70 ton | 750 mm | 400 mm | 450 mm | 800 mm | 2218 mm | 200 mm |

| DLP-28 | 22 – 32 ton | 2550 kg | 80 ton | 840 mm | 425 mm | 520 mm | 850 mm | 2300 mm | 200 mm |

| DLP-36 | 26 – 40 ton | 3200 kg | 100 ton | 950 mm | 460 mm | 550 mm | 880 mm | 2450 mm | 200 mm |

| DLP-50 | 32 – 55 ton | 4200 kg | 115 ton | 1075 mm | 500 mm | 600 mm | 1000 mm | 2600 mm | 250 mm |

| *Depending of lifting capacity of carrier | |||||||||

| **Excl adapter |

Download our free

ProLine DLP brochure

Want to know more about our ProLine Rotating pulverizers?

Download the brochure for more info by filling out the form below.

Related products

Request quote

We will get back to you as soon as possible.

Frequently asked questions

Can’t find what you are looking for?

Here are the most asked questions and their answers!

What demolition recycling scrap handling and construction attachments are included in Demarec’s product range?

Demarec has separate product lines with the PremiumLine and ProLine for Demolition and Recycling,

Scrap and Recycling, and Construction. Key tools include demolition and sorting grabs,

pulverizers, multi quick processors, two cylinder concrete crushers, hydraulic hammers, multi shears, drum cutters, scrap shears, rail cutters, polyp grabs, rotatable pulverizers, tilt rotators and more.

How does the patented DemaPower System boost the power and cycle speed of Demarec tools?

The four chamber DemaPower cylinder delivers about twenty five percent more closing force and cycles faster because two chambers work on the in stroke and two on the out stroke. A double acting speed valve keeps oil moving both ways, so the jaw opens and closes in roughly five seconds while staying within normal excavator pressure.

Where can I obtain spare parts maintenance, repairs for my Demarec attachment or who do I call for urgent technical assistance if my Demarec tool develops a fault on site after purchase?

Demarec runs an in house service department and After Sales portal. For help you can phone +31 485 442 300 option 2 for parts or option 3 for service, or write to parts@demarec.com and service@demarec.com. Local dealers worldwide can also supply parts and support.

I would like to represent Demarec what steps should I follow to become an authorised dealer?

Fill out the short enquiry form on the Become our dealer page. Demarec will review the details and respond directly.

Does Demarec offer training facilities to dealers?

Yes we have our inhouse training center for service and sales.

How do I determine which Demarec attachment model fits the size and hydraulic capacity of my carrier excavator or material handler?

Every product page and brochure includes a technical specification table that lists carrier weight windows, tool weight, oil flow and pressure. Match your machine to those ranges or ask Demarec service for confirmation. Example: DRG selector grabs cover carriers from ten to eighty tons with detailed specs-per-model.