Scrap & Recycling

PremiumLine Scrap & Recycling Attachments

PremiumLine Scrap & Recycling attachments are designed to meet the highest demands of the scrap and recycling industry. Developed through years of experience and close attention to real-world needs, this range delivers maximum force, fast cycle times, and low fuel consumption. Each product is engineered for an optimal weight-to-performance ratio and minimal maintenance, so you achieve the best results in even the toughest environments.

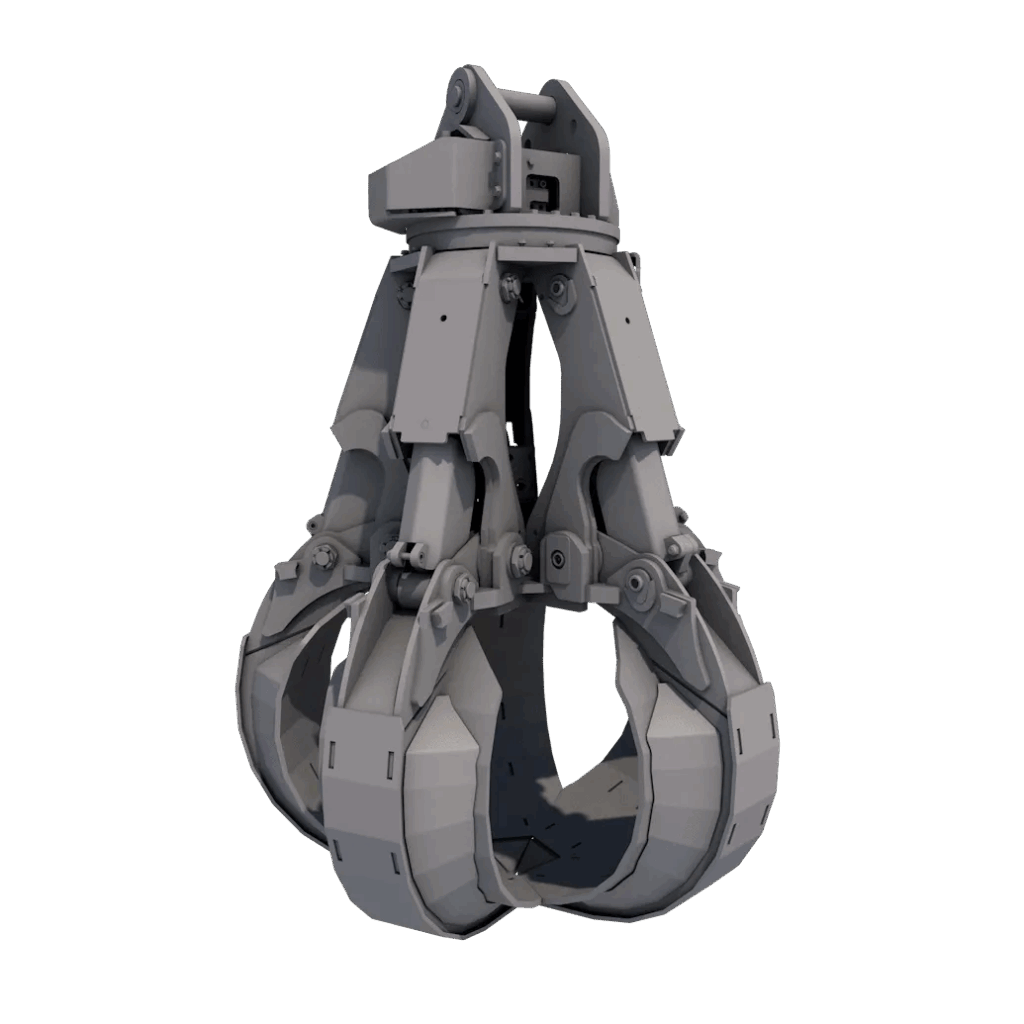

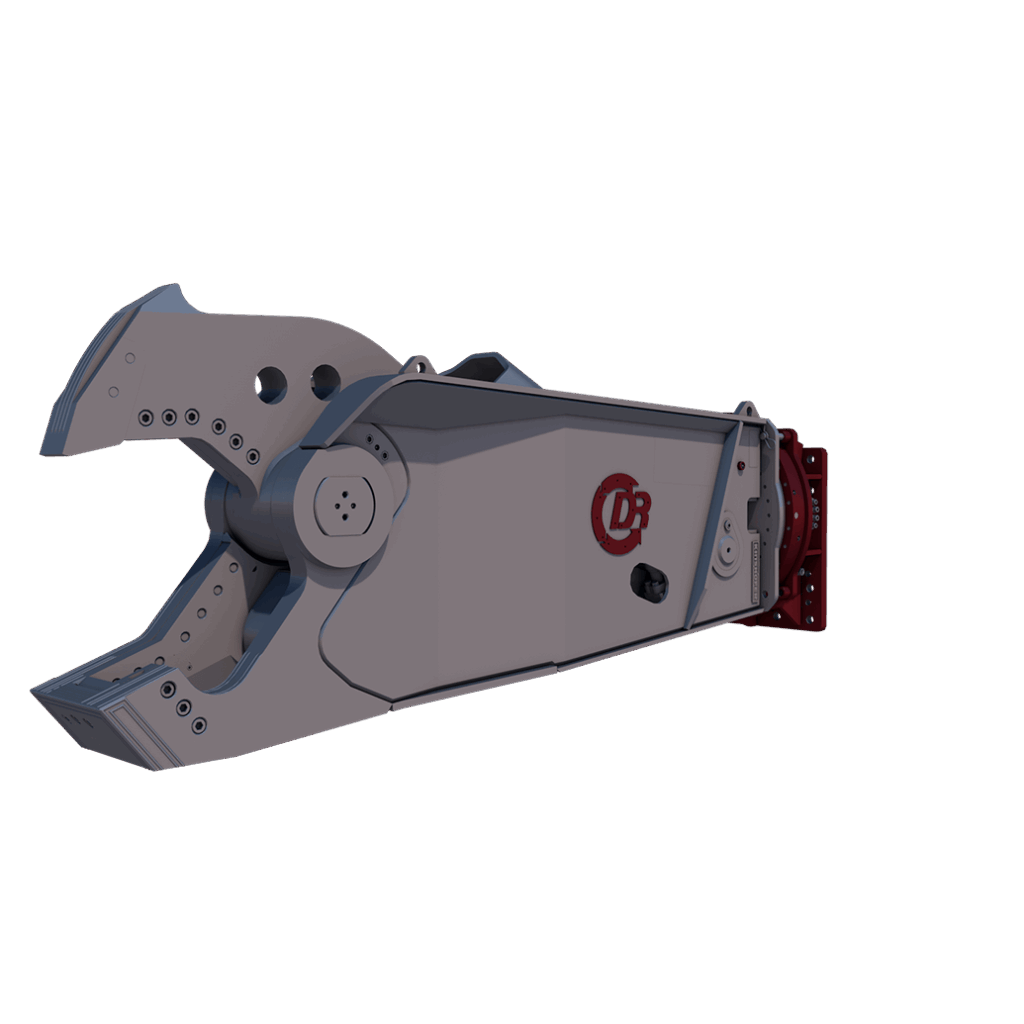

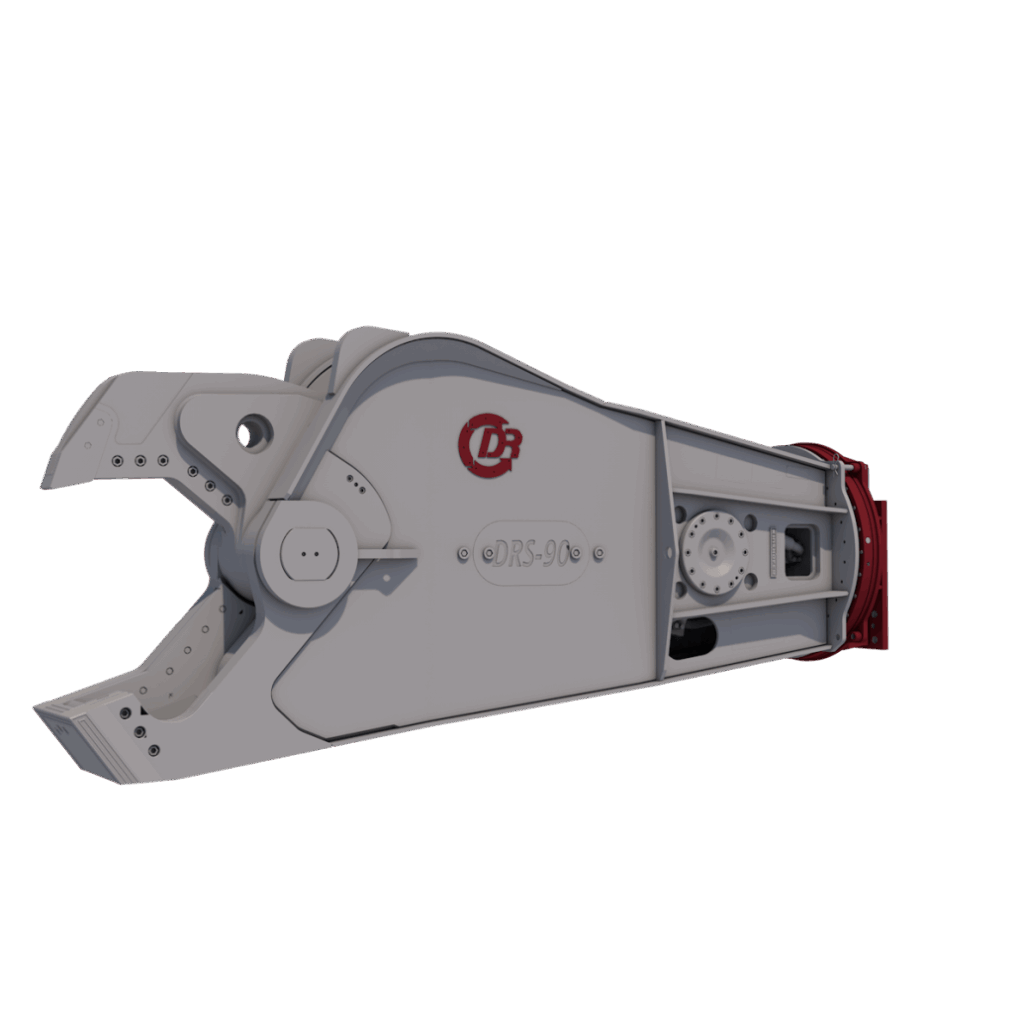

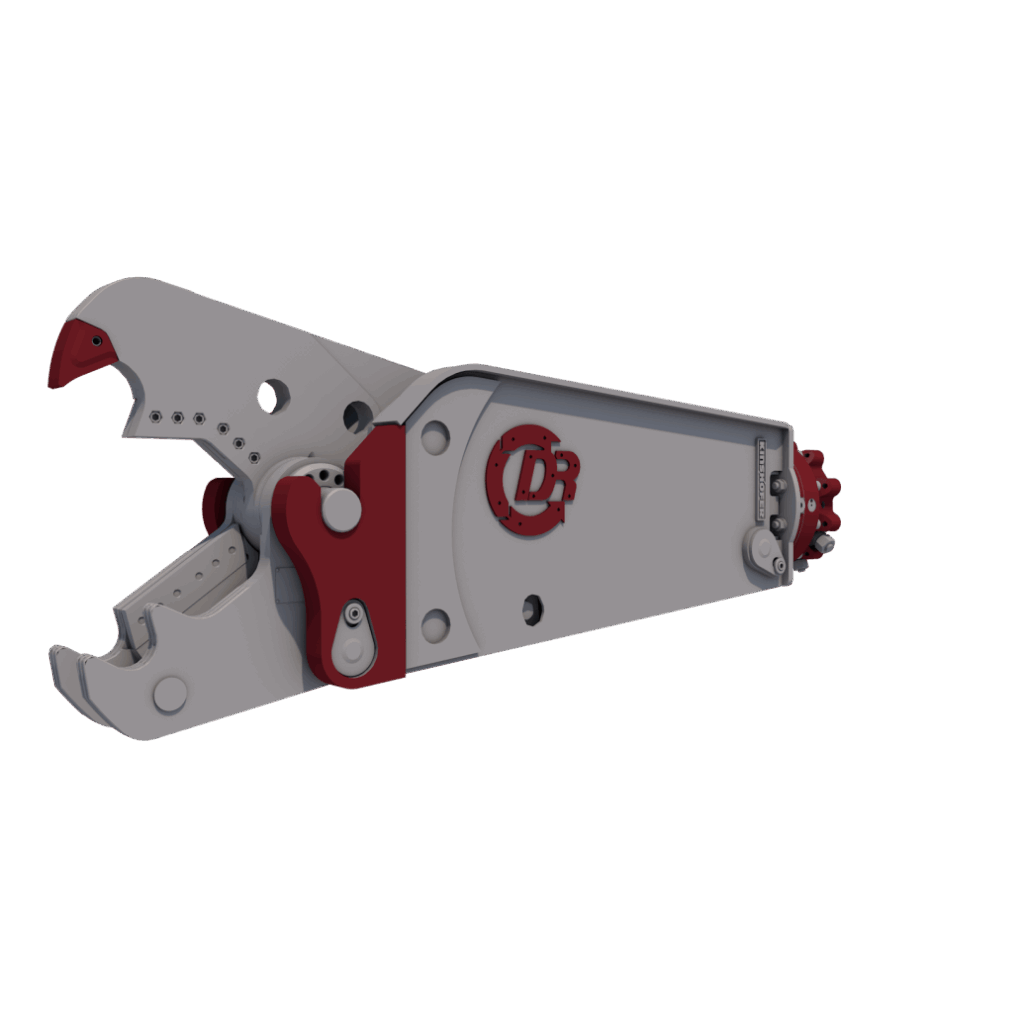

Within this collection, you’ll find versatile multi-shears, heavy-duty scrap shears, and reliable polypgrabs, all built with innovation and sustainability in mind. Rapid jaw change systems, robust cylinders, and advanced protection for moving parts ensure lasting performance and efficiency. Choose from attachments for all carrier sizes, with options for 360° rotation and multiple mounting styles to match your workflow.

Whether you’re processing steel, handling scrap, or tackling mixed recycling, PremiumLine tools guarantee high productivity, low downtime, and a customer-friendly design. Backed by a global support network, these attachments help your business build on past successes and seize new opportunities in the ever-changing scrap and recycling market.

Scrap & Recycling products

Frequently asked questions

Can’t find what you are looking for?

Here are the most asked questions and their answers!

What demolition recycling scrap handling and construction attachments are included in Demarec’s product range?

Demarec has separate product lines with the PremiumLine and ProLine for Demolition and Recycling,

Scrap and Recycling, and Construction. Key tools include demolition and sorting grabs,

pulverizers, multi quick processors, two cylinder concrete crushers, hydraulic hammers, multi shears, drum cutters, scrap shears, rail cutters, polyp grabs, rotatable pulverizers, tilt rotators and more.

How does the patented DemaPower System boost the power and cycle speed of Demarec tools?

The four chamber DemaPower cylinder delivers about twenty five percent more closing force and cycles faster because two chambers work on the in stroke and two on the out stroke. A double acting speed valve keeps oil moving both ways, so the jaw opens and closes in roughly five seconds while staying within normal excavator pressure.

Where can I obtain spare parts maintenance, repairs for my Demarec attachment or who do I call for urgent technical assistance if my Demarec tool develops a fault on site after purchase?

Demarec runs an in house service department and After Sales portal. For help you can phone +31 485 442 300 option 2 for parts or option 3 for service, or write to parts@demarec.com and service@demarec.com. Local dealers worldwide can also supply parts and support.

I would like to represent Demarec what steps should I follow to become an authorised dealer?

Fill out the short enquiry form on the Become our dealer page. Demarec will review the details and respond directly.

Does Demarec offer training facilities to dealers?

Yes we have our inhouse training center for service and sales.

How do I determine which Demarec attachment model fits the size and hydraulic capacity of my carrier excavator or material handler?

Every product page and brochure includes a technical specification table that lists carrier weight windows, tool weight, oil flow and pressure. Match your machine to those ranges or ask Demarec service for confirmation. Example: DRG selector grabs cover carriers from ten to eighty tons with detailed specs-per-model.