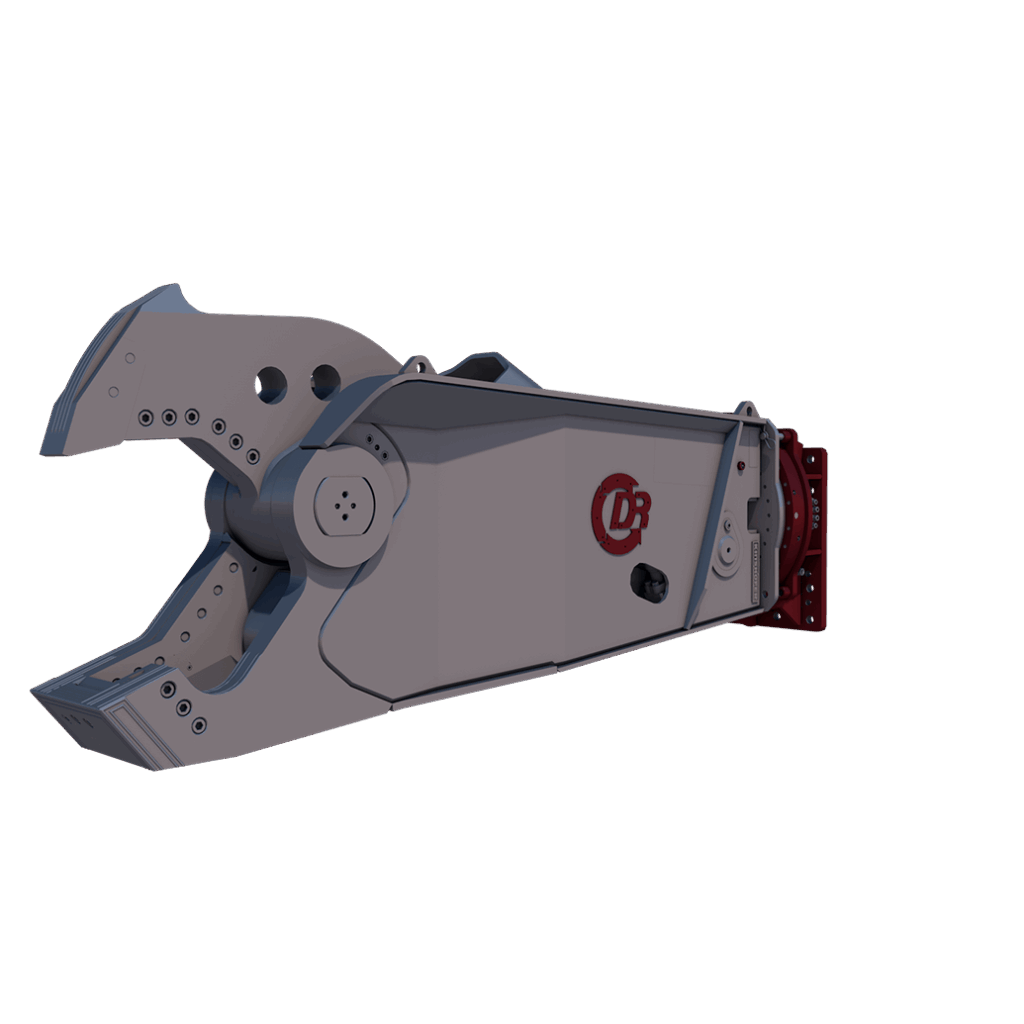

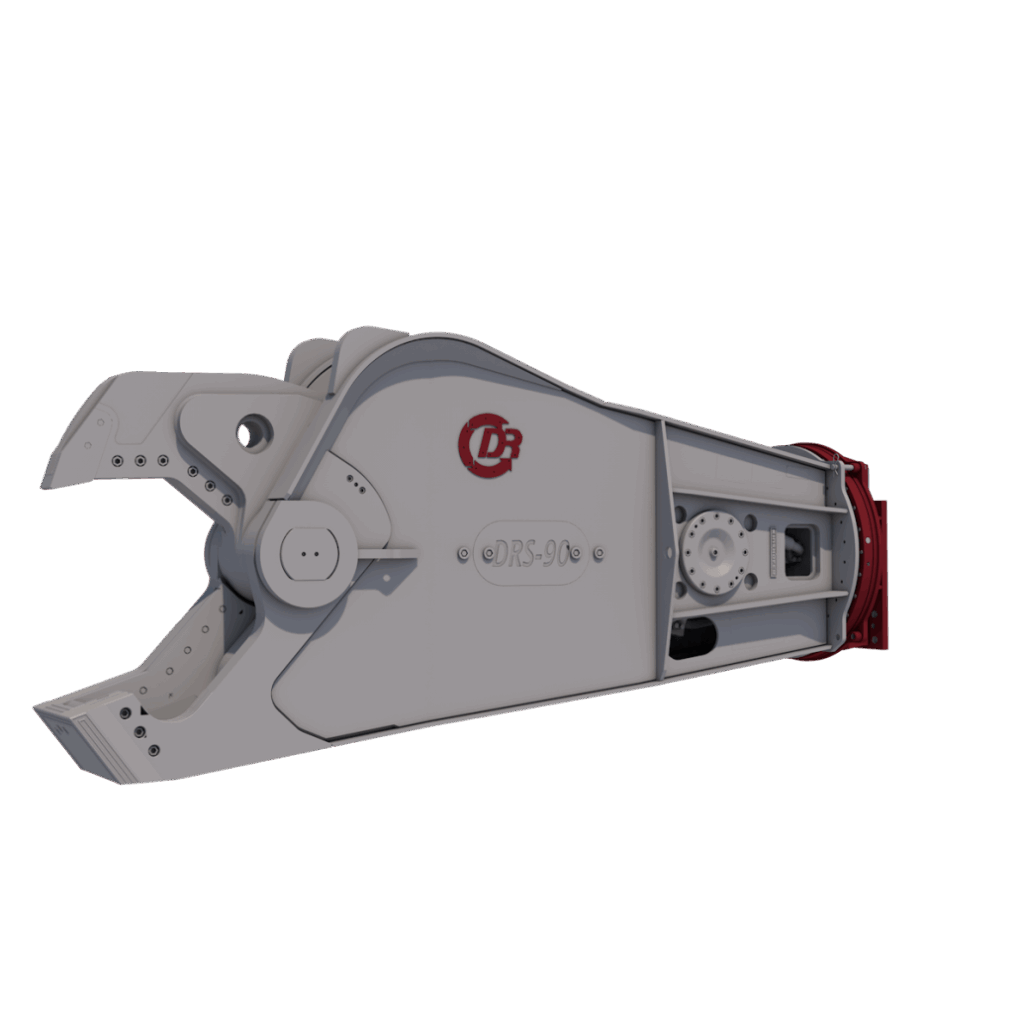

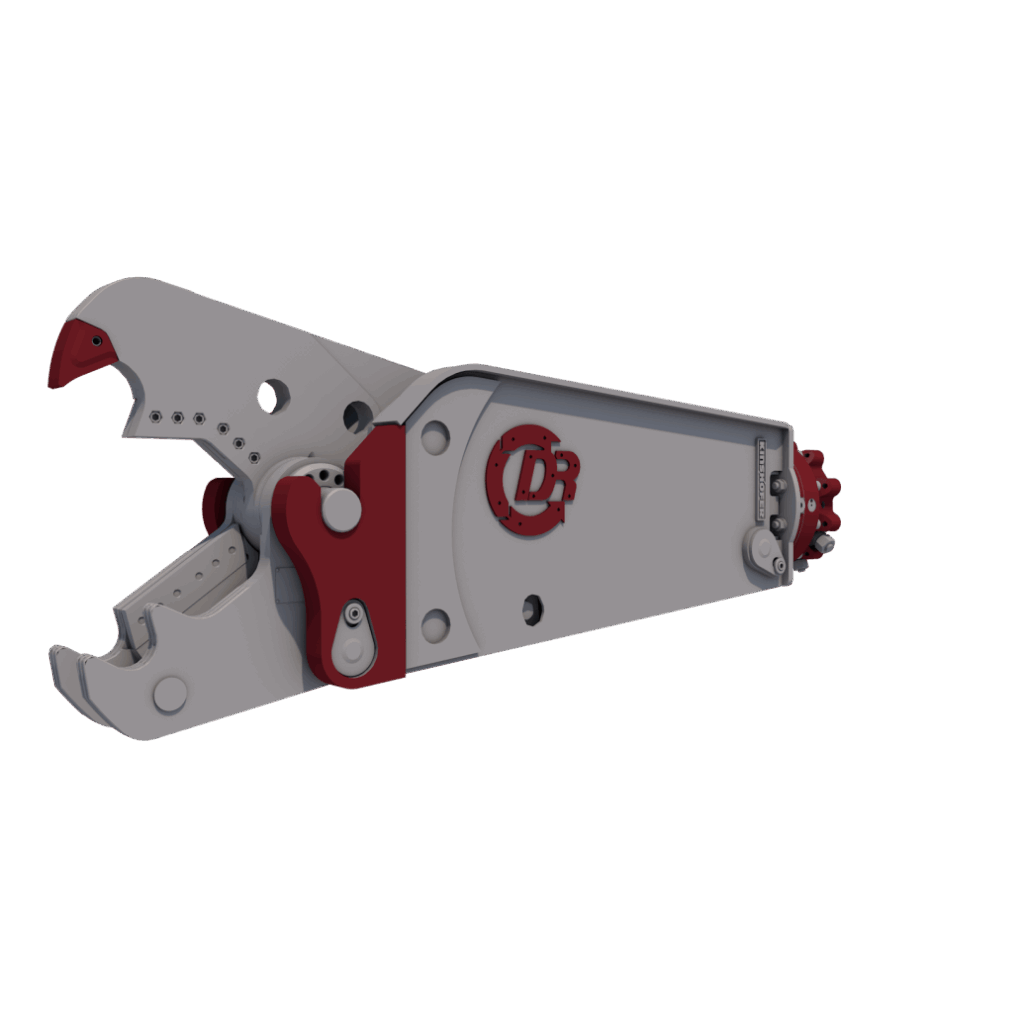

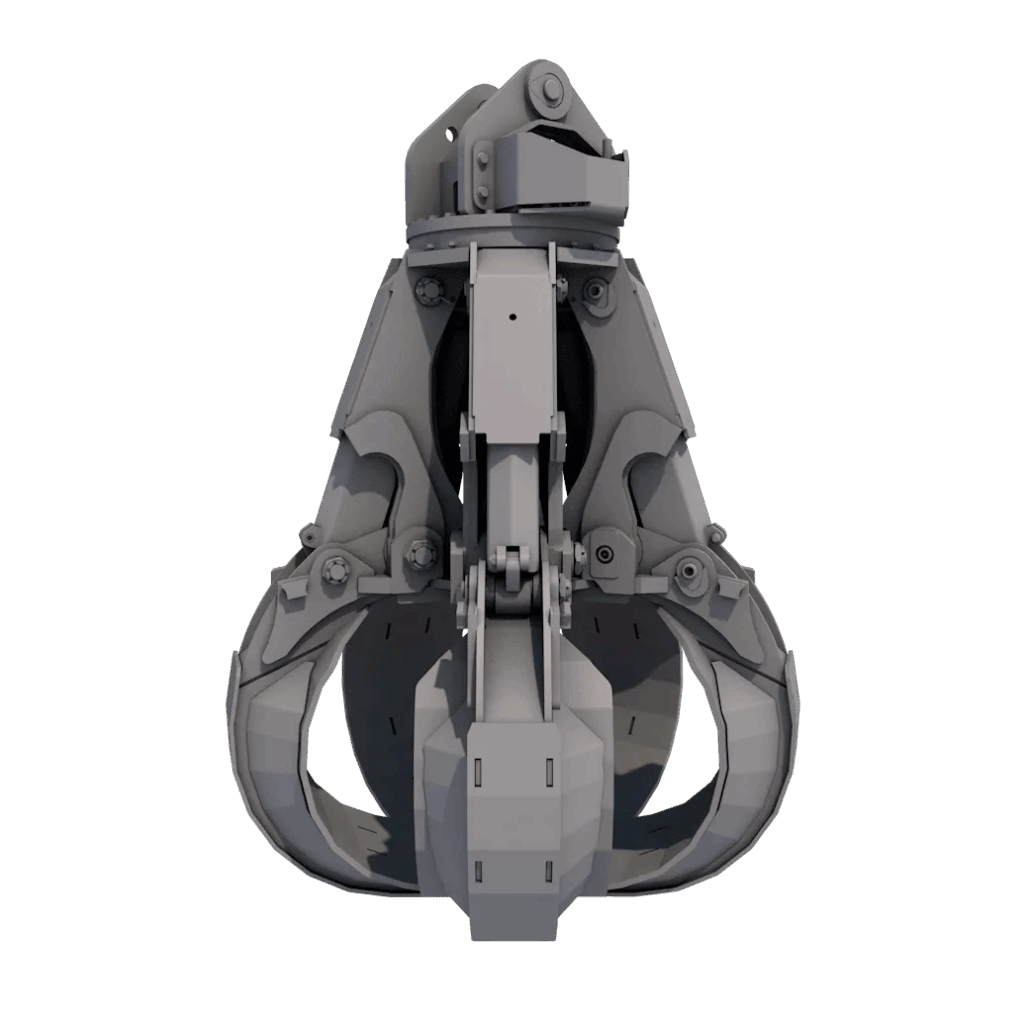

Polyp grab

Orange Peel

Grapple

The Demarec polypgrab meets the most important requirements of the customers. The Demarec Orange Peel Grapple with its two different types of 360 ° rotation is designed to provide a Orange Peel Grapple for handling bulky materials with maximum closing force and optimum weight / performance ratio in daily use.

maximum volume

of 5000 Liters

This robust tool can be used for a wide variety of jobs, e.g. scrap metal processing. Orange Peel Grapple with 4 or 5 tines and 450 liter volume for handling coarse scrap metal with excavators from 16t to 22t operating weight, or as a heavy version (HD series) for excavators from 20t to 200t operating weight and with a maximum volume of 5000 liters.

Maximum closing forceuse

and optimum weight &

performance ratio for daily

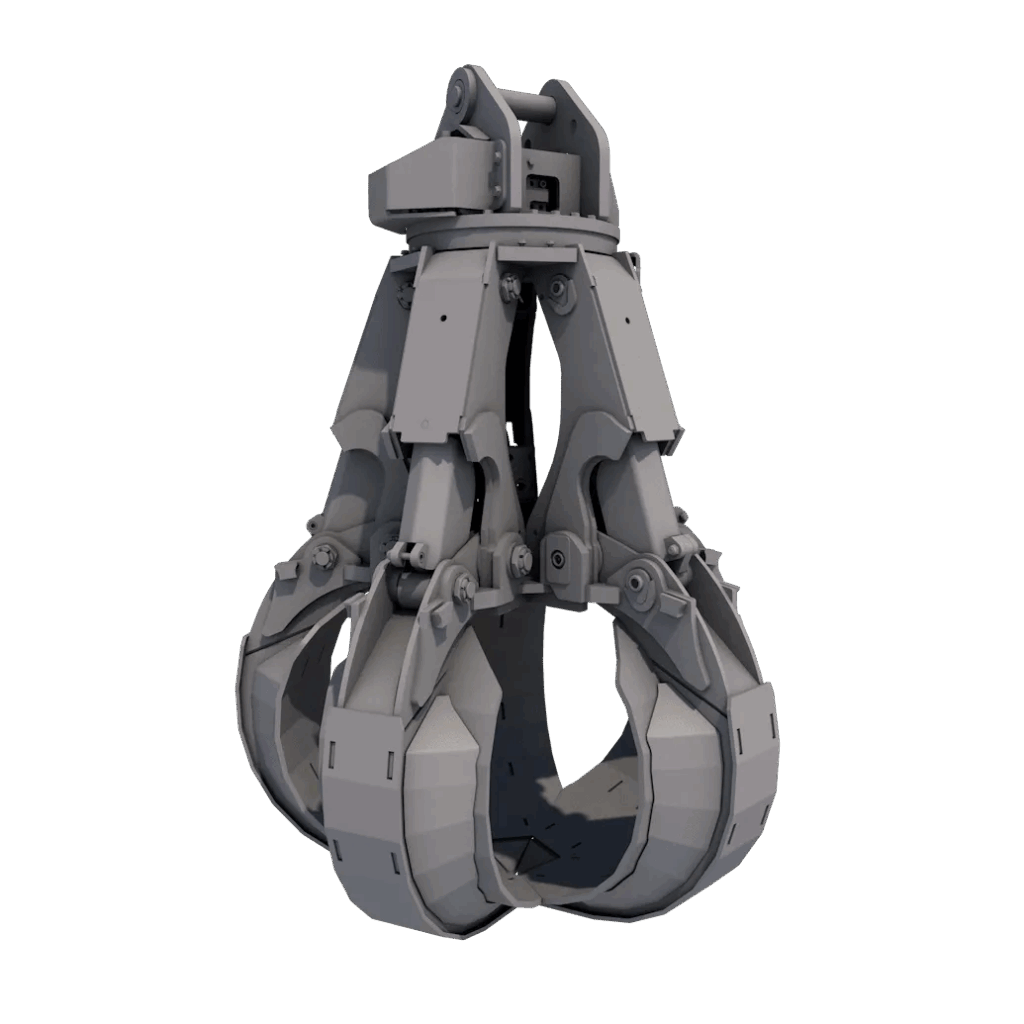

Key features & benefits

Rotation

Robust, fully integrated rotation

With sturdy swivel head and internal hoses against hose breakage

Optimal power transmission

Integrated pressure relief valve against overload

Gland and bevel sealed; rotating feed-through and motor directly accessible (P30 – P200)

Main carrier

Wrap around design of main carrier protects hydraulic cylinders and hydraulic hoses 100%

Good access to hoses and oil distributor thanks to easily removable covers

Mounting of radiation detector or magnet possible

Hydraulics

Maximum working pressure 350 bar

Hydraulic cylinders damped to protect against impact loads

Non-return valve prevents accidental pressure drop

Piston rod protection encloses the piston rod and prevents damage

Use of high pressure hoses, this allows even the highest pressures caused by impact to be absorbed

Weight / performance ratio

All components are optimized for tension and weight with FEM: means 10% weight reduction with 20% stress reduction

Use of fine grain steel with high strength

All wear plates made of highly wear resistant steel 400 HB

Bearings

Generously sized pin joints reduce surface pressure

Induction hardened pins are in steel bushings

Tooth heads and main bearings are widely spaced to accommodate deformation and reduce surface pressure in the bushings

Lateral pressure discs provide solid support for the teeth and reduce wear to a minimum

Tooth

Slim, contour optimized tine guarantees ideal penetration

No protruding parts, ensures perfect removal of the goods

Huge limit stops relieve the hydraulics in extreme positions

The ideal tooth circumference prevents materials from sticking that could potentially damage the cylinder

Forged tips of teeth 500 HB

| Type | Machineweight* | Flow open/close (l/min) | Rotation Pmax (bar) | Number of tines | Volume (litre) | Closing fore** (kN) | Self weight of tines (kg) | Opening A (mm) | Width E (mm) | Height C max. (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| DPG-22 | 16 – 22 t | 50-150 | 320 | 4 – 5 | 450 | 17 | 810 – 1145 | 1910 | 1370 | 1545 |

| DPG-30 | 20 – 30 t | 120 – 200 | 170 | 4 – 5 | 600 | 27 | 1310 – 1830 | 2130 – 2290 | 1520 – 1525 | 1980 – 2065 |

| DPG-40-3 | 26 – 40 t | 120 – 200 | 170 | 3 | 600 | 38 | 1390 – 2045 | 2200 – 2835 | 1420 – 1860 | 2065 |

| DPG-40 | 26 – 40 t | 120 – 200 | 170 | 4 – 5 | 800 | 38 | 1530 – 2140 | 2165 – 2190 | 1430 – 1560 | 2170 |

| DPG-51 | 36 – 50 t | 200 – 350 | 200 | 4 – 5 | 1000 | 33 | 1570 – 2300 | 2440 – 2830 | 1610 – 1870 | 2200 – 2500 |

| DPG-80 | 50 – 80t | 200 – 350 | 200 | 4 – 5 | 2500 | 40 | 2500 – 3420 | 2770 – 3180 | 2010 – 2325 | 2770 – 3155 |

| DPG-120 | 80 – 120 t | 200 – 350 | 140 – 250 | 5 | 3000 | 61 | 4220 – 4700 | 3200 – 3910 | 2280 – 2390 | 3180 – 3350 |

| DPG-P-25 | 18 – 25 t | 50-200 | 170 | 3 | 600 | 38 | 1650 – 1780 | 2200 – 2250 | 1420 – 1560 | 1775 – 1780 |

| * Machine weight is indicative. |

Download our free

DPG brochure

Want to know more about our Polyp grabs?

Download the brochure for more info by filling out the form below.

Related products

Request quote

We will get back to you as soon as possible.

Frequently asked questions

Can’t find what you are looking for?

Here are the most asked questions and their answers!

What demolition recycling scrap handling and construction attachments are included in Demarec’s product range?

Demarec has separate product lines with the PremiumLine and ProLine for Demolition and Recycling,

Scrap and Recycling, and Construction. Key tools include demolition and sorting grabs,

pulverizers, multi quick processors, two cylinder concrete crushers, hydraulic hammers, multi shears, drum cutters, scrap shears, rail cutters, polyp grabs, rotatable pulverizers, tilt rotators and more.

How does the patented DemaPower System boost the power and cycle speed of Demarec tools?

The four chamber DemaPower cylinder delivers about twenty five percent more closing force and cycles faster because two chambers work on the in stroke and two on the out stroke. A double acting speed valve keeps oil moving both ways, so the jaw opens and closes in roughly five seconds while staying within normal excavator pressure.

Where can I obtain spare parts maintenance, repairs for my Demarec attachment or who do I call for urgent technical assistance if my Demarec tool develops a fault on site after purchase?

Demarec runs an in house service department and After Sales portal. For help you can phone +31 485 442 300 option 2 for parts or option 3 for service, or write to parts@demarec.com and service@demarec.com. Local dealers worldwide can also supply parts and support.

I would like to represent Demarec what steps should I follow to become an authorised dealer?

Fill out the short enquiry form on the Become our dealer page. Demarec will review the details and respond directly.

Does Demarec offer training facilities to dealers?

Yes we have our inhouse training center for service and sales.

How do I determine which Demarec attachment model fits the size and hydraulic capacity of my carrier excavator or material handler?

Every product page and brochure includes a technical specification table that lists carrier weight windows, tool weight, oil flow and pressure. Match your machine to those ranges or ask Demarec service for confirmation. Example: DRG selector grabs cover carriers from ten to eighty tons with detailed specs-per-model.