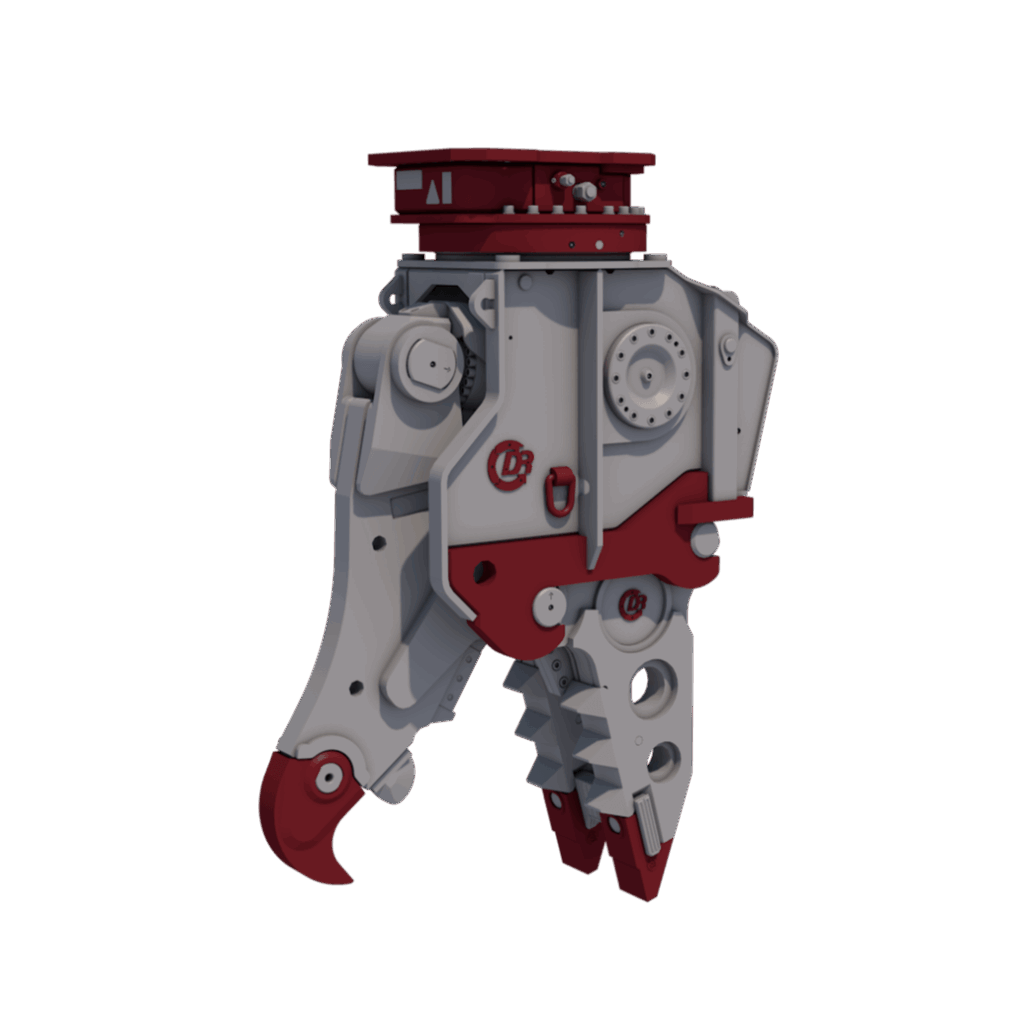

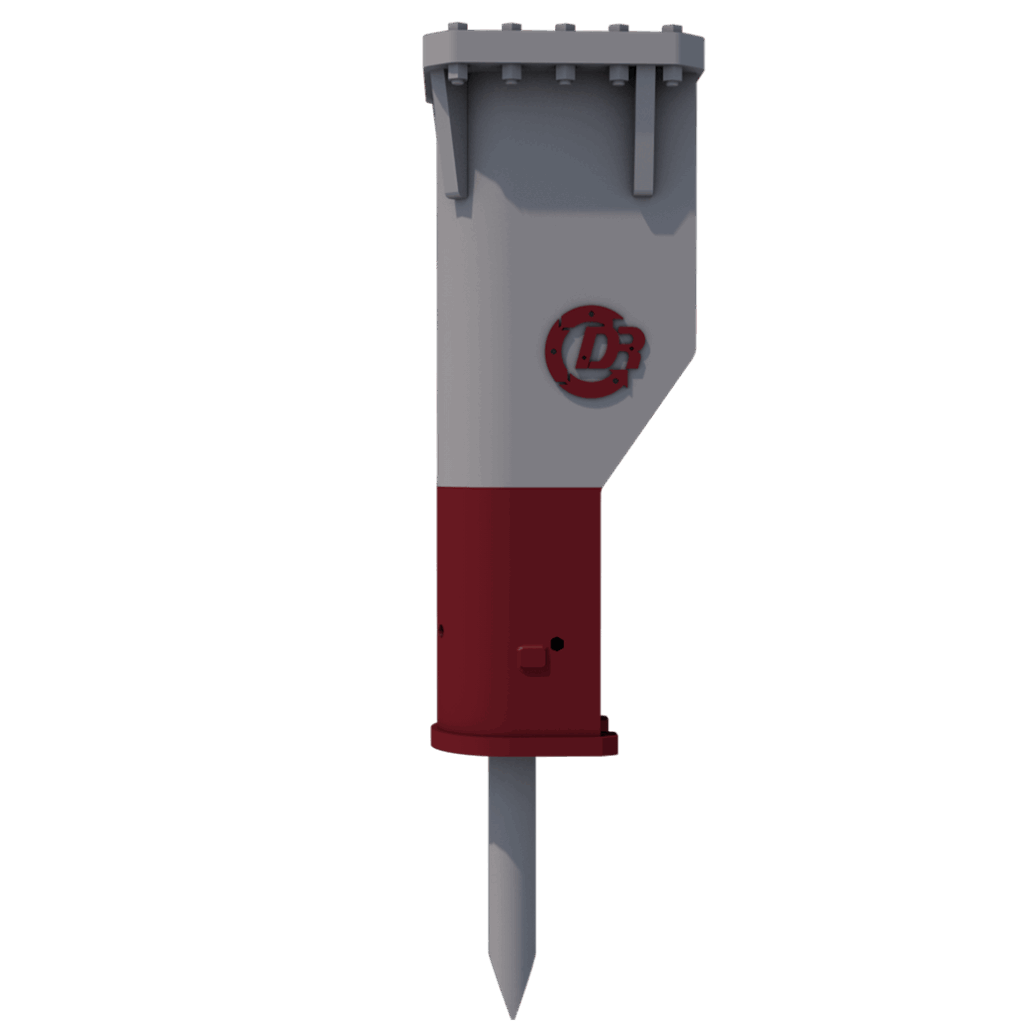

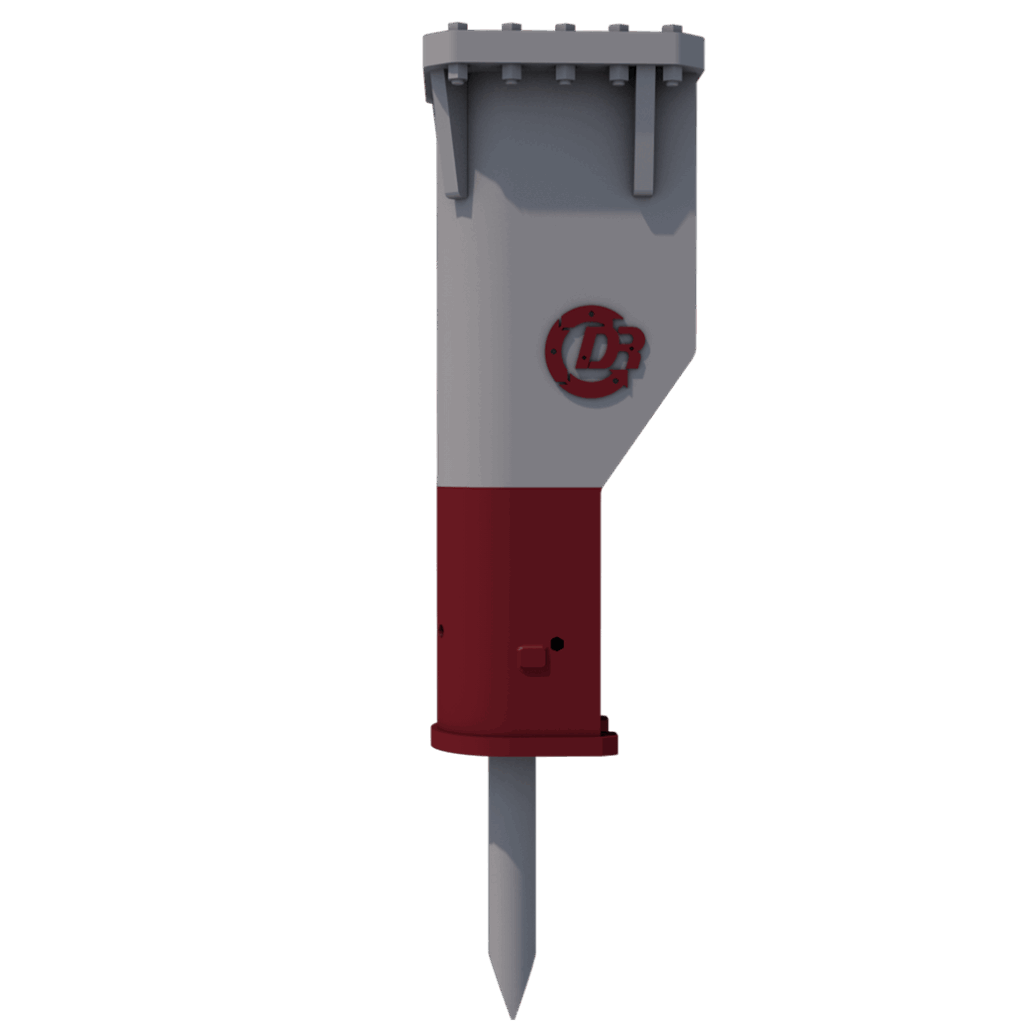

Hydraulic hammer

very simple design

less parts and easy to service

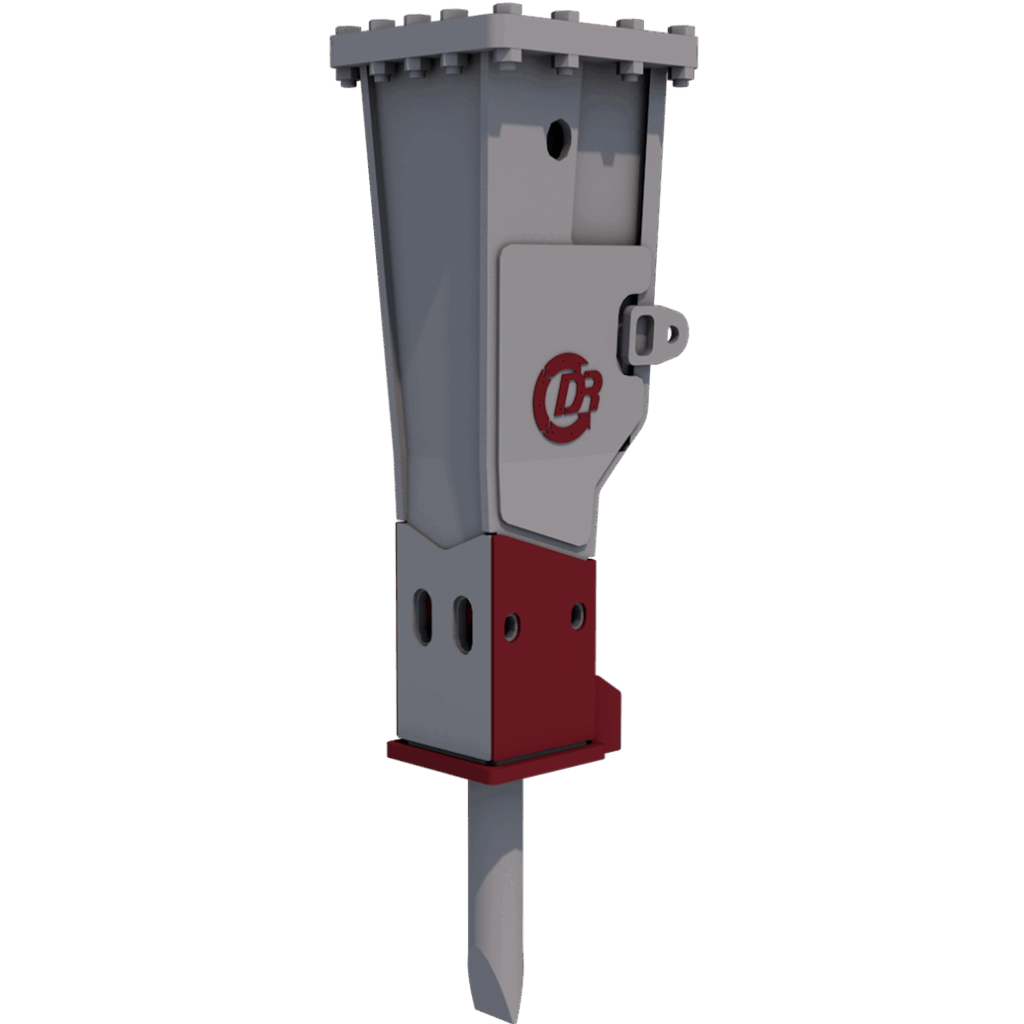

The Demarec hammers of the DSB series are suitable for carriers, mini excavators, mini-blades, backhoe loaders, demolition robots. etc.. The breakers of the DSB series, thanks to their power and efficiency and to the right relationship between weight and power are suitable for primary and secondary demolition work, in urban areas and f.e. galleries. The DSB series are “MonoBloc-Hammers”, a very simple design, less parts and easy to service.

A combination of

punchingpower and innovation

Key features & benefits

More power and less vibration and maintenance

The DSB breakers work with inertial nitrogen energy recovery, obtaining more power (more than 30%) and less vibration thanks to the nitrogen chamber which reduces maintenance costs, since it has no diaphragms inside it.

Long lasting of the nitrogen charge

In the past, energy recovery breakers required frequent nitrogen refills; with the new sealing system and the new compound developed by Freudenberg they are able to guarantee a gas tightness equal to 300% more than in the past.

Only two moving parts

tolerates high back pressure

For all types of installations (pressurization). The DSB series tolerates high back pressure values and has a wide calibration range of the required oil flow, in order to facilitate installation.

Silenced body

The particular construction, with a closed box casing as well as the insertion of sound-absorbing material, allowed to reach very low noise levels for a breaker.

Double retainer pin

The tool locking system with double retainer pin allows an adequate and uniform wear of the same and ensures longer maintenance intervals for the whole locking system.

Monobloc body without tie rods

The entire DSB series benefit from the particular monobloc construction; this feature gives the structure a very high resistance to leverage, during work. The breaker is built in one only piece and it is without tie rods, thus obtaining more production and less maintenance for our customers.

Single interchangeable cylinder liner

The piston moves in a single interchangeable cylinder liner, easy to replace in case of necessity, keeping intact the main body.

Protected tubes

The tubes are completely protected through the casing and they’re suitable for every type of excavation, especially in narrow spaces.

Constant energy of impact

Piston constructed with a special geometry such as to keep a constant energy of impact, as well as reducing breakages in conditions of criticality.

Visibility and versatility

The breakers of the DSB series, with their tapered shape, provide the operator with an excellent view during the work and allow to operate close to the walls, both in narrow section and with open front.

constant energy of impact

Piston constructed with a special geometry such as to keep a constant energy of impact, as well as reducing breakages in conditions of criticality.

| Type | Carrier Weight* | Weight** | Height*** | Chisel diameter | Flow | Oil pressure | Max back pressure |

|---|---|---|---|---|---|---|---|

| DSB-0 | 0,5 – 1,4 ton | 60 kg | 783 mm | 40 mm | 15 – 20 l/min | 110 bar | 30 bar |

| DSB-1 | 0,5 – 2,5 ton | 70 kg | 810 mm | 40 mm | 13 – 20 l/min | 140 bar | 30 bar |

| DSB-2 | 1,2 – 3,5 ton | 100 kg | 920 mm | 45 mm | 15 – 30 l/min | 150 bar | 30 bar |

| DSB-3 | 1,5 – 4,5 ton | 145 kg | 920 mm | 48 mm | 18 – 40 l/min | 150 bar | 30 bar |

| DSB-4 | 2,5-6,5 ton | 190 kg | 1145 mm | 55 mm | 25 – 55 l/min | 170 bar | 30 bar |

| DBS-6 | 3,0-8,0 ton | 250 kg | 1170 mm | 65 mm | 30 – 60 l/min | 180 bar | 30 bar |

| DSB-8 | 4,5-9,0 ton | 320 kg | 1200 mm | 75 mm | 50 – 70 l/min | 200 bar | 30 bar |

| DSQ-12 | 8-11 ton | 500 kg | 1580 mm | 85 mm | 65 – 90 l/min | 170 bar | 30 bar |

*Depending of capacity of carrier

**Weigth excluding bracket

*** With standard tool

Subject to change without notice.

Download our free

DSB & DSQ brochure

Want to know more about our Hydraulic Hammers?

Download the brochure for more info by filling out the form below.

Related products

Request quote

We will get back to you as soon as possible.

Frequently asked questions

Can’t find what you are looking for?

Here are the most asked questions and their answers!

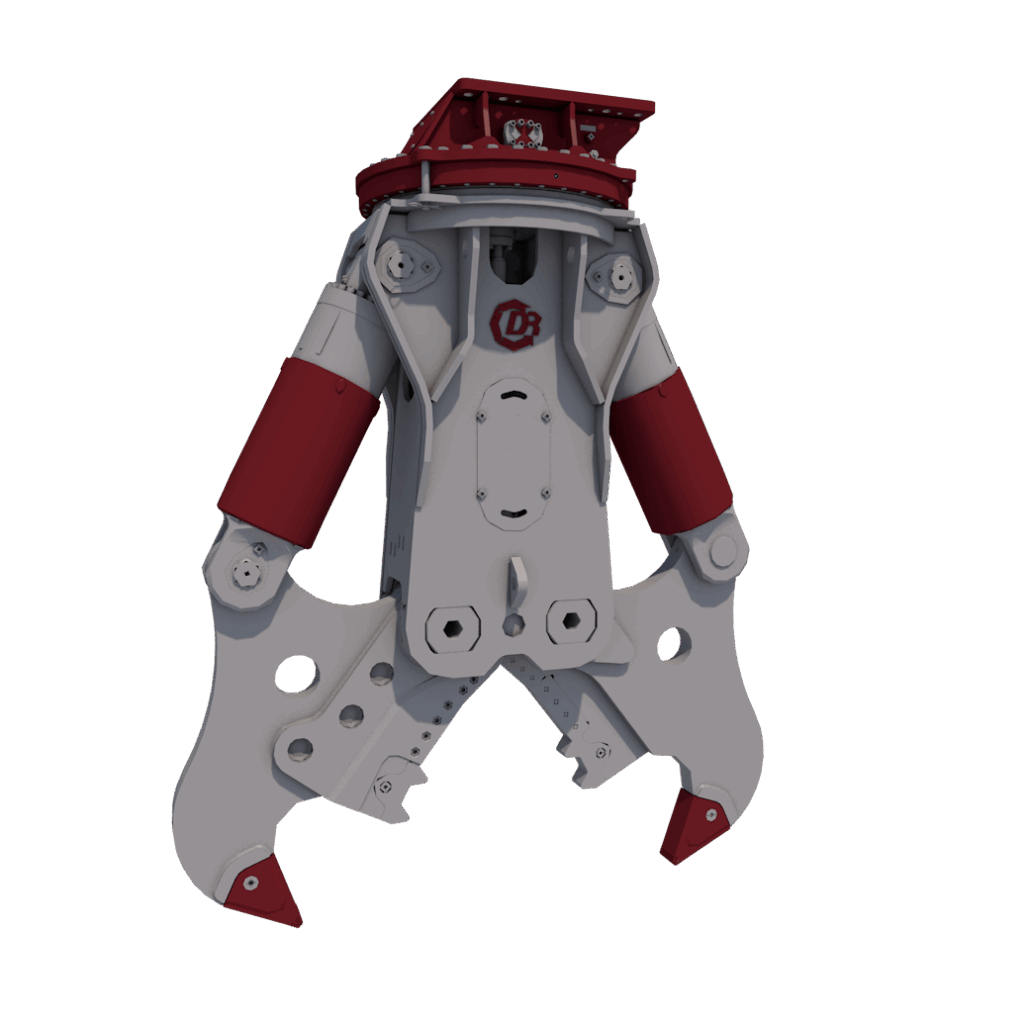

What demolition recycling scrap handling and construction attachments are included in Demarec’s product range?

Demarec has separate product lines with the PremiumLine and ProLine for Demolition and Recycling,

Scrap and Recycling, and Construction. Key tools include demolition and sorting grabs,

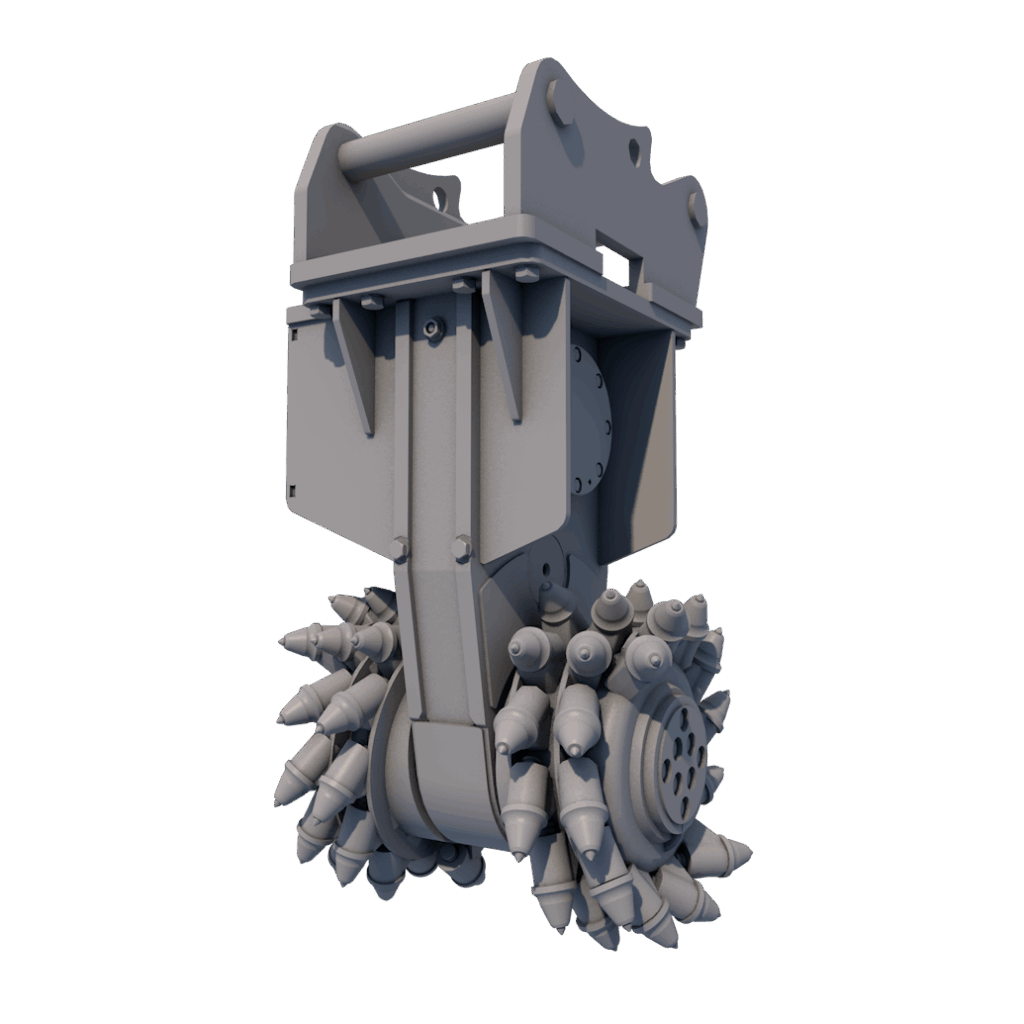

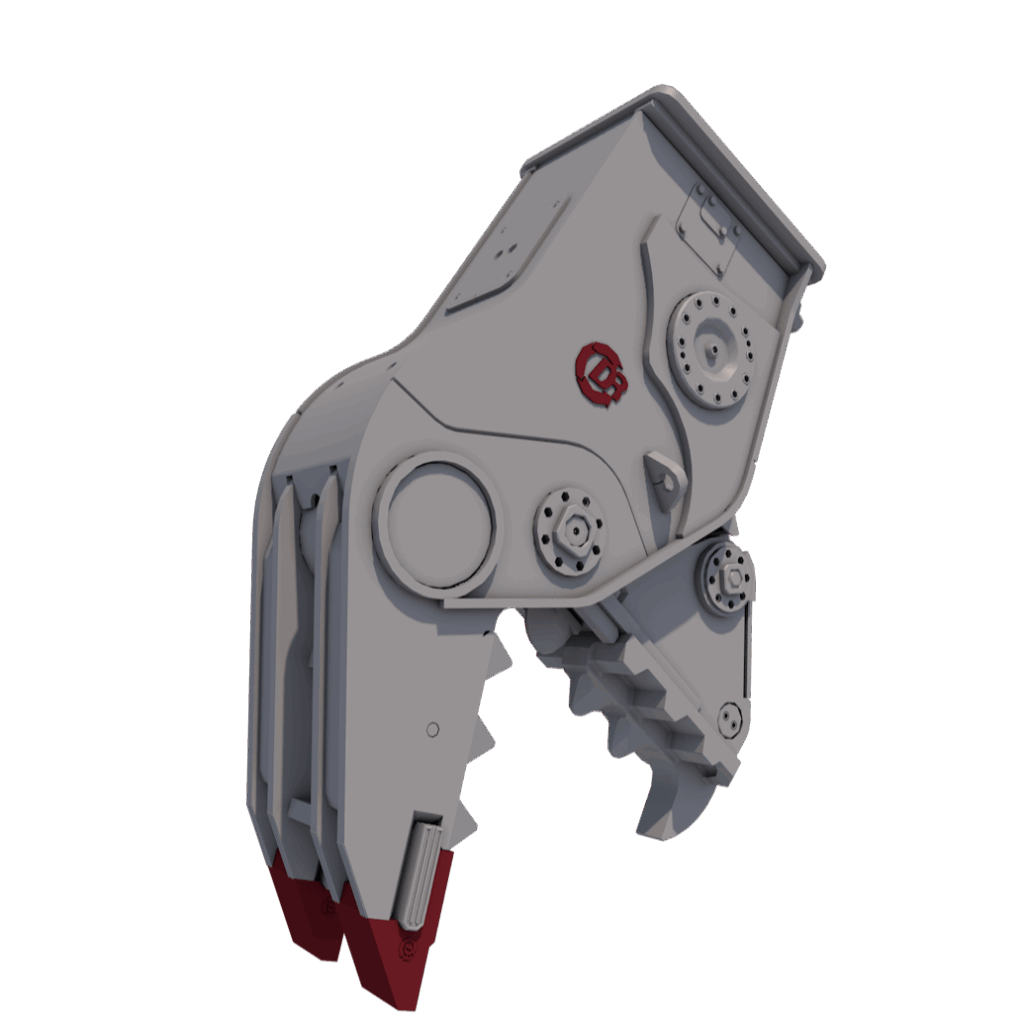

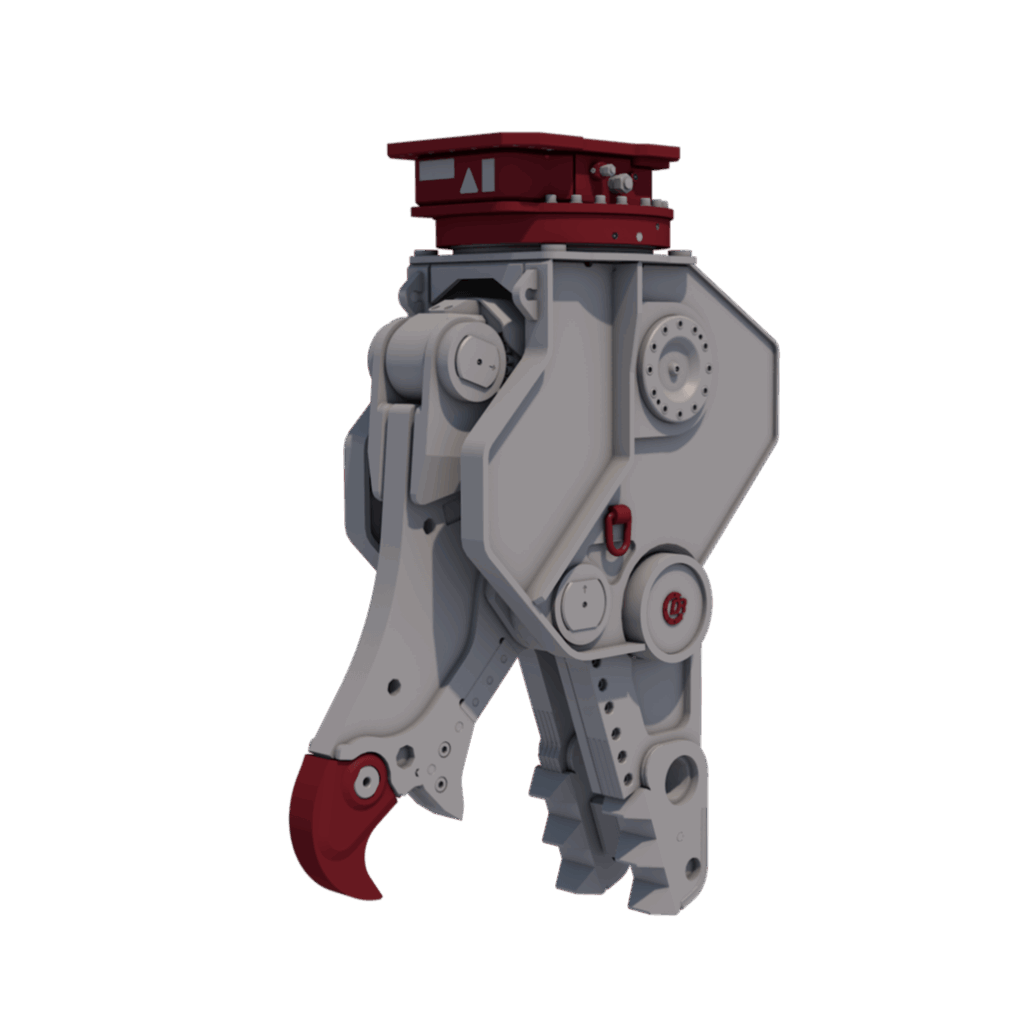

pulverizers, multi quick processors, two cylinder concrete crushers, hydraulic hammers, multi shears, drum cutters, scrap shears, rail cutters, polyp grabs, rotatable pulverizers, tilt rotators and more.

How does the patented DemaPower System boost the power and cycle speed of Demarec tools?

The four chamber DemaPower cylinder delivers about twenty five percent more closing force and cycles faster because two chambers work on the in stroke and two on the out stroke. A double acting speed valve keeps oil moving both ways, so the jaw opens and closes in roughly five seconds while staying within normal excavator pressure.

Where can I obtain spare parts maintenance, repairs for my Demarec attachment or who do I call for urgent technical assistance if my Demarec tool develops a fault on site after purchase?

Demarec runs an in house service department and After Sales portal. For help you can phone +31 485 442 300 option 2 for parts or option 3 for service, or write to parts@demarec.com and service@demarec.com. Local dealers worldwide can also supply parts and support.

I would like to represent Demarec what steps should I follow to become an authorised dealer?

Fill out the short enquiry form on the Become our dealer page. Demarec will review the details and respond directly.

Does Demarec offer training facilities to dealers?

Yes we have our inhouse training center for service and sales.

How do I determine which Demarec attachment model fits the size and hydraulic capacity of my carrier excavator or material handler?

Every product page and brochure includes a technical specification table that lists carrier weight windows, tool weight, oil flow and pressure. Match your machine to those ranges or ask Demarec service for confirmation. Example: DRG selector grabs cover carriers from ten to eighty tons with detailed specs-per-model.